- Table of Contents

- Introduction

- What Is Corrosion in the Oil and Gas Industry?

- The Most Common Corrosion Issues in Oil and Gas

- 1. Uniform Corrosion

- 2. Localised Corrosion

- 3. Microbiologically Influenced Corrosion (MIC)

- Why Is It Important to Prevent Corrosion in Oil and Gas?

- Safety Imperative

- Operational Efficiency at Stake

- Financial Impact

- Environmental Responsibility

- Preserving Assets for Long-Term Viability

- How to Control Corrosion in Oil and Gas

- 1. Material Selection

- 2. Protective Coatings

- 3. Cathodic Protection

- 4. Monitoring Systems

- 5. Corrosion Inhibitors

- 6. pH Control

- Challenges of Controlling Corrosion in Oil and Gas

- Harsh Operating Environments

- Complexity of Infrastructure

- Budgetary Constraints

- Continuous Research and Development

- Personnel Safety Concerns

- Environmental Impact

- Corrosion Under Insulation (CUI)

- Embracing Innovation: Technology's Role in Controlling Corrosion

- Advanced Monitoring Systems

- Corrosion Modelling and Simulation

- Drones and Robotics

- Predictive Analytics and Machine Learning

- Remote Monitoring and Control

- Conclusion

Introduction

Corrosion is an insidious adversary that quietly undermines the integrity of structures in the oil and gas industry. As an ever-present concern, it poses a significant risk to equipment, pipelines, and facilities. In this blog post, we will delve into the depths of corrosion, exploring its various forms, the reasons why it must be prevented, and the strategies employed to control and combat this pervasive challenge.

What Is Corrosion in the Oil and Gas Industry?

Corrosion, in the context of the oil and gas industry, is the gradual degradation of materials due to chemical reactions with the surrounding environment. It is an electrochemical process that often involves the interaction of metals with corrosive agents, such as moisture, oxygen, sulphur compounds, and other contaminants present in the harsh operating conditions of oil and gas facilities.

The Most Common Corrosion Issues in Oil and Gas

Corrosion in the oil and gas industry manifests in a variety of forms, each presenting unique challenges and risks. Understanding these different types is crucial for implementing targeted preventive measures. Let's delve into the most common corrosion issues faced by the industry:

1. Uniform Corrosion

Uniform corrosion is akin to the slow erosion of metal surfaces, occurring uniformly across the entire exposed area. While this may seem like a gradual process, the cumulative effect can compromise the integrity of crucial components over time. Picture a scenario where a pipeline steadily loses material thickness, eventually leading to weakened structural integrity.

One of the primary culprits behind uniform corrosion is atmospheric exposure. Moisture, oxygen, and other environmental factors contribute to the gradual degradation of metals. In offshore environments, the corrosive effects of saltwater exacerbate the challenge, necessitating the use of corrosion-resistant alloys and protective coatings to mitigate the impact.

2. Localised Corrosion

Unlike the widespread impact of uniform corrosion, localised corrosion targets specific areas, resulting in more concentrated and potentially severe damage. Pitting corrosion, crevice corrosion, and stress corrosion cracking are three prevalent forms of localised corrosion in the oil and gas industry:

- Pitting Corrosion

Pitting corrosion appears as small, localised pits on the metal surface, often initiating in microscopic imperfections. These pits can penetrate deep into the material, creating points of weakness that compromise structural integrity. Pitting is particularly insidious because it can go unnoticed until significant damage has occurred.

- Crevice Corrosion

Crevice corrosion occurs in confined spaces or gaps between surfaces where moisture and corrosive agents accumulate. This type of corrosion is common in flanges, gaskets, and areas with tight clearances. Effective prevention involves proper sealing and the use of corrosion-resistant materials in such vulnerable zones.

- Stress Corrosion Cracking

Stress corrosion cracking is a phenomenon where the combination of mechanical stress and a corrosive environment leads to the formation of cracks in the material. This type of corrosion is especially concerning as it can result in sudden and catastrophic failures. Managing stress factors through proper design and material selection is essential to prevent stress corrosion cracking.

3. Microbiologically Influenced Corrosion (MIC)

Microorganisms, despite their microscopic size, can wreak havoc on metal structures in the oil and gas industry through Microbiologically Influenced Corrosion (MIC). Bacteria, fungi, and algae form biofilms on surfaces, creating an environment conducive to corrosion. The byproducts of microbial metabolism can accelerate the corrosive process, posing a significant threat to pipelines and equipment.

Preventing MIC involves a multifaceted approach. Biocides are often introduced into systems to control microbial growth, while regular monitoring and maintenance practices help detect and address potential issues before they escalate. The complexity of MIC makes it a challenging form of corrosion to combat, requiring ongoing research and innovation in preventive strategies.

Understanding these common types of corrosion issues provides a foundation for developing targeted prevention and mitigation measures. As the oil and gas industry navigates the intricate challenges posed by corrosion, staying one step ahead in the battle against each form is imperative for ensuring the longevity and safety of critical infrastructure.

Why Is It Important to Prevent Corrosion in Oil and Gas?

According toOnePetro, more than a quarter of failures in the oil and gas industry stem from corrosion-related issues, accounting for over 25% of reported failures. The ramifications of corrosion in the oil and gas industry are profound and can have far-reaching consequences, which is why prevention is paramount, among other reasons:

Safety Imperative

Safety is paramount in the oil and gas industry, where operations involve hazardous materials, high pressures, and complex processes. Corrosion weakens the structural integrity of equipment, pipelines, and facilities, elevating the risk of catastrophic failures. Unchecked corrosion could lead to leaks, ruptures, or collapses, putting both personnel and the surrounding environment in jeopardy. Prevention becomes a non-negotiable measure to ensure the well-being of workers and the communities in proximity to these operations.

Operational Efficiency at Stake

Corrosion-related failures can be disruptive, causing unplanned downtime and interrupting production schedules. The financial ramifications of such interruptions can be staggering, with repairs and replacements often incurring substantial costs. In fact, the oil and gas industry in the United States bears an estimated annual corrosion cost of $27 billion, as per NACE International, cited in the book ‘Corrosion Control in the Oil and Gas Industry.’ This figure has prompted projections suggesting that the global annual corrosion expense for the industry surpasses $60 billion. The prevention of corrosion is, therefore, integral to maintaining operational efficiency. By safeguarding against unforeseen failures, the industry ensures a continuous and smooth flow of production, optimising resources and maximising output.

Financial Impact

Beyond the direct costs of repairing or replacing corroded infrastructure, there are additional financial implications associated with corrosion. Environmental fines resulting from leaks or spills can impose significant financial burdens on companies. Moreover, the cumulative effect of ongoing repairs and replacements due to corrosion can strain budgets. Proactive prevention, though an initial investment, proves cost-effective in the long run by mitigating these financial risks.

Environmental Responsibility

The oil and gas industry operates under increased scrutiny due to its environmental impact. Corrosion-induced leaks or spills have the potential to contaminate soil, water, and air, causing lasting ecological damage. Preventing corrosion aligns with the industry's commitment to environmental responsibility. By minimising the risk of leaks and spills, the industry demonstrates a dedication to preserving ecosystems and minimising its ecological footprint.

Preserving Assets for Long-Term Viability

Oil and gas facilities are colossal investments, and their longevity directly influences the economic viability of the industry. Corrosion, if left unchecked, can significantly reduce the lifespan of critical infrastructure. Preventive measures, such as material selection, protective coatings, and monitoring systems, safeguard these assets, ensuring they remain productive and contribute to the industry's long-term viability.

In essence, the imperative to prevent corrosion in the oil and gas industry transcends mere maintenance concerns. It is an ethical obligation to protect human lives, preserve the environment, and secure the industry's economic sustainability. The proactive pursuit of corrosion prevention reflects a commitment to responsible and resilient operations, mitigating risks and fortifying the industry against the corrosive challenges that could otherwise erode its foundations.

How to Control Corrosion in Oil and Gas

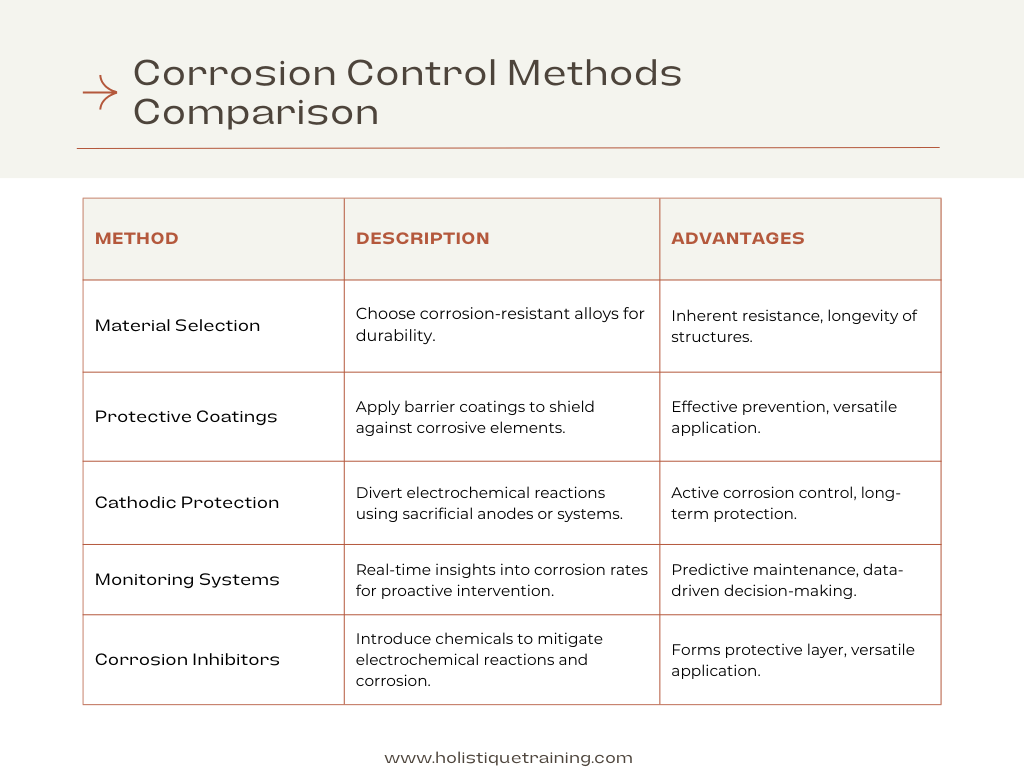

Controlling corrosion requires a comprehensive approach that addresses various aspects of the operating environment. Here are some effective strategies:

1. Material Selection

One of the initial lines of defence against corrosion is selecting materials with inherent resistance to corrosive agents. Stainless steels, nickel alloys, and corrosion-resistant alloys are frequently employed in the construction of critical components. These materials exhibit a natural resilience to the corrosive effects of moisture, oxygen, and other contaminants, providing a robust foundation for corrosion control.

2. Protective Coatings

Applying protective coatings to metal surfaces is a widely adopted strategy for creating a barrier between the material and the corrosive environment. These coatings act as a shield, preventing direct contact and inhibiting corrosion reactions. Epoxy, polyurethane, and zinc coatings are common choices, tailored to specific operational conditions and environmental challenges.

3. Cathodic Protection

Cathodic protection is a proven method for controlling corrosion by manipulating the electrochemical reactions that lead to material degradation. This technique involves the introduction of a direct current to the metal structure, diverting the corrosion process. Two primary methods of cathodic protection are employed:

- Sacrificial Anodes

Sacrificial anodes, typically composed of zinc, aluminium, or magnesium, are attached to the metal structure. These sacrificial metals corrode preferentially, protecting the critical components from corrosion.

- Impressed Current Systems

In impressed current systems, an external power source applies a controlled direct current to the metal structure, actively preventing corrosion. This method is particularly effective in high-corrosion-risk environments.

4. Monitoring Systems

Real-time monitoring of corrosion rates is essential for timely intervention and preventive measures. Advanced monitoring systems utilise sensors and data analytics to track the corrosive activity in different components of the infrastructure. This enables operators to detect potential issues before they escalate, allowing for targeted and efficient corrosion control strategies.

5. Corrosion Inhibitors

Corrosion inhibitors are chemical compounds introduced into the system to mitigate the electrochemical reactions that lead to corrosion. These inhibitors form a protective layer on the metal surface, hindering the corrosive process. Organic and inorganic inhibitors are tailored to specific operational conditions, providing flexibility in application.

6. pH Control

Maintaining optimal pH levels in the operating environment is a crucial aspect of corrosion control. Adjusting the acidity or alkalinity of the system can significantly impact the corrosive activity. By carefully managing the pH, operators create an environment less conducive to corrosive reactions, contributing to long-term corrosion prevention.

Incorporating these strategies into the overall corrosion control plan allows the oil and gas industry to proactively manage the impact of harsh operating conditions. The synergy of material science, protective coatings, advanced technologies, and chemical interventions forms a robust defence against corrosion, ensuring the integrity and reliability of critical infrastructure in the dynamic landscape of oil and gas operations.

Challenges of Controlling Corrosion in Oil and Gas

While the strategies for controlling corrosion in the oil and gas industry are robust, the landscape is not without its challenges. Successfully implementing corrosion control measures requires an understanding of the complexities inherent in this dynamic sector. Here, we delve into the formidable challenges faced by the industry in its relentless pursuit to conquer corrosion:

Harsh Operating Environments

Oil and gas facilities often operate in extreme conditions, including high temperatures, pressures, and corrosive atmospheres. These harsh environments intensify the corrosive impact on metal structures. Adapting corrosion prevention measures to withstand such conditions necessitates continuous innovation and the development of materials and coatings capable of withstanding the rigours of the operating environment.

Complexity of Infrastructure

The oil and gas industry boasts a vast and intricate infrastructure, comprising pipelines, drilling rigs, processing facilities, and more. Implementing uniform corrosion prevention measures across such diverse components is a significant challenge. Tailoring strategies to address the specific corrosion risks associated with each segment of the system requires a nuanced understanding of the infrastructure's intricacies.

Budgetary Constraints

While the long-term benefits of corrosion prevention are evident, the upfront costs of implementing state-of-the-art technologies can be substantial. Balancing the financial implications of corrosion control measures with budgetary constraints poses a challenge for the industry. Striking the right balance between cost-effectiveness and the efficacy of preventive measures is crucial for sustainable corrosion management.

Continuous Research and Development

Corrosion is an ever-evolving challenge, demanding continuous research and development efforts. As new materials, coatings, and technologies emerge, the industry must stay at the forefront of innovation to effectively combat corrosion. The need for ongoing research to address emerging forms of corrosion and improve existing preventive measures adds another layer of complexity to corrosion control efforts.

Personnel Safety Concerns

Implementing corrosion control measures often involves maintenance activities that can pose safety risks to personnel. Navigating these risks while ensuring the integrity of corrosion prevention strategies requires meticulous planning and adherence to safety protocols. Striking a balance between the need for regular inspections and minimising risks to personnel remains an ongoing challenge.

Environmental Impact

While corrosion prevention is crucial for ensuring the integrity of oil and gas infrastructure, the environmental impact of certain preventive measures must be carefully considered. For example, the disposal of spent sacrificial anodes or the environmental effects of certain corrosion inhibitors can raise environmental concerns. Achieving a balance between effective corrosion control and environmental responsibility requires a comprehensive approach.

Corrosion Under Insulation (CUI)

Corrosion under insulation is a specific challenge where corrosive processes occur beneath insulation materials, making detection and prevention more challenging. Inspecting and maintaining insulated components present unique hurdles, and developing effective strategies to mitigateCUI is an ongoing focus for the industry.

In short, while the oil and gas industry has made significant strides in the realm of corrosion prevention, challenges persist. Navigating the harsh operating environments, addressing the complexity of infrastructure, managing budgetary constraints, and staying at the forefront of research and development are ongoing tasks. However, it is through a combination of innovation, collaboration, and a commitment to safety and sustainability that the industry can successfully overcome these challenges and fortify itself against the relentless forces of corrosion.

Table 1: Metrics for Measuring the Effectiveness of Corrosion Control Methods

Metric | Description | Significance |

Corrosion Rate Reduction | Measure of how much corrosion is mitigated over time. | Direct indicator of method's preventative impact. |

System Downtime Reduction | Reduction in the frequency and duration of shutdowns. | Minimises disruptions, optimising operational efficiency. |

Cost Savings from Prevention | Economic benefits gained by preventing corrosion issues. | Reflects the financial impact of effective corrosion control. |

Longevity of Infrastructure | Extension of the operational lifespan of critical components. | Indicates sustained integrity and reliability. |

Environmental Impact | Assessment of the method's ecological consequences and responsibility. | Balancing corrosion control with environmental considerations. |

Embracing Innovation: Technology's Role in Controlling Corrosion

As the oil and gas industry evolves, technology emerges as a formidable ally in the battle against corrosion. Cutting-edge advancements empower the sector to enhance preventive strategies and overcome traditional challenges. Here's a glimpse into how technology is reshaping corrosion control:

Advanced Monitoring Systems

State-of-the-art monitoring systems equipped with sensors, IoT connectivity, and data analytics provide real-time insights into corrosion rates. This allows for predictive maintenance, enabling operators to address potential issues before they escalate. Continuous monitoring enhances the industry's ability to proactively manage corrosion risks.

Corrosion Modelling and Simulation

Computational tools and corrosion modelling software offer a virtual testing ground for corrosion control strategies. By simulating various conditions, operators can optimise preventive measures and tailor them to specific environments. This technology-driven approach allows for more precise and efficient corrosion management.

Drones and Robotics

Drones equipped with advanced sensors and cameras are employed for aerial inspections of pipelines and structures, reaching areas that are challenging to access manually. Similarly, robotic systems designed for underwater inspections enhance the industry's ability to assess and address corrosion in offshore environments. These technologies minimise safety risks while providing comprehensive insights.

Predictive Analytics and Machine Learning

Predictive analytics and machine learning algorithms analyse historical data to predict future corrosion trends. This proactive approach allows operators to implement preventive measures based on data-driven insights, optimising the effectiveness of corrosion control strategies and minimising the risk of unexpected failures.

Remote Monitoring and Control

Remote monitoring systems enable operators to oversee corrosion control measures from a centralised location. This not only streamlines operations but also facilitates quick responses to emerging corrosion issues. The ability to remotely monitor and control corrosion prevention measures enhances efficiency and reduces the need for on-site interventions.

As technology continues to advance, the oil and gas industry stands to benefit from these innovative solutions in the ongoing fight against corrosion. Embracing these technological tools not only improves the effectiveness of corrosion control but also contributes to safer, more sustainable, and resilient operations in this dynamic sector.

Conclusion

In conclusion, the battle against corrosion in the oil and gas industry is an ongoing struggle that demands vigilance, innovation, and a commitment to safety. By understanding the diverse forms of corrosion, implementing effective prevention strategies, and leveraging advanced technologies, the industry can fortify itself against this silent threat, ensuring the longevity and reliability of its infrastructure. As we continue to explore new frontiers in energy extraction, the fight against corrosion remains a crucial aspect of securing a sustainable and resilient future for the oil and gas sector.

In your quest to conquer corrosion challenges in the oil and gas industry, equip yourself with the knowledge and expertise needed to stay ahead. Our comprehensive online course, ‘Corrosion Control in the Oil and Gas Sector,’ is designed for industry professionals seeking cutting-edge insights and practical strategies. Delve into the complexities of corrosion prevention, learn to navigate harsh operating environments, and discover the latest advancements in materials and technologies. Join us in this transformative journey towards mastering corrosion control – an investment not only in your professional growth but also in securing the integrity of critical infrastructure. Be a proactive guardian against corrosion, ensuring a sustainable and resilient future for the oil and gas sector. Enrol now and become a frontline defender in the battle against this silent threat!