- Table of Contents

- Introduction

- What is Procurement?

- The Procurement Process

- 1. Need Identification

- 2. Supplier Research

- 3. Supplier Negotiation

- 4. Purchase Order Issuance

- 5. Delivery and Inspection

- 6. Invoice Processing and Payment

- 7. Supplier Relationship Management

- 8. Contract Management

- 9. Risk Management

- 10. Review and Analysis

- Procurement Technologies and Their Effect on Supply Chain

- What Are the Supply Chain Entities?

- 1. Suppliers

- 2. Manufacturers

- 3. Distributors

- 4. Retailers

- 5. Customers

- What is Supply Chain Management?

- Why is Supply Chain Management Important?

- 1. Cost Reduction

- 2. Improved Customer Satisfaction

- 3. Risk Management

- 4. Enhancing Competitiveness

- 5. Sustainability

- Five Steps of Supply Chain Management

- 1. Planning

- 2. Sourcing

- 3. Manufacturing

- 4. Delivery

- 5. Return

- Procurement vs. Supply Chain: Key Differences

- 1. Scope and Focus

- 2. Activities and Processes

- 3. Objectives and Goals

- 4. Strategic vs. Operational Role

- 5. Interdependency and Interaction

- How Procurement Decisions Impact the Supply Chain and Vice Versa

- Conclusion

Introduction

Every successful business hinges on efficiently managing resources and delivering products or services to its customers. Two critical functions that enable this efficiency are procurement and supply chain management. Though these terms are often used interchangeably, they encompass distinct processes and responsibilities that play unique roles in the overall operation of a company. Procurement involves the acquisition of goods and services necessary for a company's operations, focusing on securing the best value in terms of cost, quality, and delivery. Supply chain management, however, covers the broader spectrum, overseeing the entire flow of goods, services, and information from the initial sourcing of raw materials to the final delivery of finished products to the customer.

Understanding the nuances between procurement and supply chain management is essential for optimising business processes and ensuring that both functions work harmoniously to drive efficiency and meet organisational goals. This blog post delves into the intricacies of procurement and supply chain management, highlighting their differences, interdependencies, and the critical role each plays in a company’s success.

What is Procurement?

Procurement refers to the strategic process of sourcing and acquiring the goods and services an organisation requires to operate effectively. It involves more than just purchasing; it is a comprehensive process that includes identifying the need for goods or services, selecting suppliers, negotiating contracts, and managing supplier relationships. Procurement aims to ensure that the organisation obtains the best value for its expenditures while minimising risks associated with purchasing.

Procurement plays a vital role in an organisation’s overall strategy, as it directly impacts cost management, quality control, and the efficiency of business operations. Effective procurement processes can lead to significant cost savings, improve the quality of inputs, and ensure that the organisation has a reliable supply of the materials and services it needs.

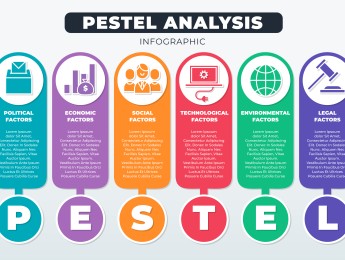

The Procurement Process

The procurement process is a structured series of steps organisations follow to acquire goods and services. Each step is crucial to ensuring that procurement is conducted efficiently, transparently, and in accordance with the organisation's objectives.

1. Need Identification

The first step in the procurement process is identifying the need for goods or services. This can arise from various sources, such as production requirements, maintenance needs, or the introduction of new projects. Accurate need identification is crucial because it sets the foundation for the entire procurement process. Understanding what is needed helps prevent over-purchasing, under-purchasing, or acquiring the wrong items.

2. Supplier Research

Once the need is identified, the next step is to research potential suppliers. This involves evaluating suppliers' ability to meet the organisation’s quality, price, delivery timelines, and reliability requirements. Supplier research may involve sending out requests for proposals (RFPs), conducting market analysis, and reviewing suppliers' past performance. The goal is to create a shortlist of suppliers capable of fulfilling the organisation's needs.

3. Supplier Negotiation

After selecting potential suppliers, the organisation enters the negotiation phase. Negotiations focus on securing the best possible terms for price, delivery schedules, payment terms, and other contractual obligations. Effective negotiation requires clearly understanding the organisation's needs, market conditions, and the supplier’s capabilities. The outcome of these negotiations is a formal agreement or contract outlining the procurement terms.

4. Purchase Order Issuance

Once the terms are agreed upon, the organisation issues a purchase order (PO) to the supplier. The PO is a formal document that details the items or services being purchased, the agreed-upon price, delivery dates, and other relevant terms. The issuance of the PO marks the official start of the procurement transaction, and it is legally binding once accepted by the supplier.

5. Delivery and Inspection

After the purchase order is issued, the supplier delivers the goods or services as specified. Upon delivery, the organisation inspects to ensure that the received goods or services meet the required standards and specifications. This step is crucial for quality control, as it helps prevent the acceptance of defective or substandard items.

6. Invoice Processing and Payment

Once the goods or services are received and inspected, the supplier submits an invoice for payment. The organisation’s accounts payable department processes the invoice, ensuring that it matches the purchase order and delivery records. After verification, the organisation processes the payment according to the agreed-upon terms.

7. Supplier Relationship Management

Procurement is not just about completing a single transaction; it involves ongoing relationship management with suppliers. This step focuses on maintaining and enhancing supplier relationships to ensure long-term cooperation and value. Effective supplier relationship management can lead to better pricing, improved service levels, and more favourable terms in future transactions.

8. Contract Management

Contract management involves overseeing the contracts established with suppliers to ensure compliance with the agreed-upon terms. This includes monitoring contract performance, addressing any issues, and making necessary amendments. Effective contract management helps mitigate risks and ensures the procurement process delivers the expected outcomes.

9. Risk Management

Procurement inherently involves various risks, including supplier defaults, price volatility, and supply chain disruptions. Risk management is about identifying, assessing, and mitigating these risks to ensure a smooth procurement process. This may involve diversifying the supplier base, negotiating flexible contracts, or implementing contingency plans.

10. Review and Analysis

The final step in the procurement process is reviewing and analysing the procurement activities to identify areas for improvement. This involves evaluating suppliers' performance, the procurement process's efficiency, and the purchases' overall cost-effectiveness. Continuous review and analysis help organisations refine their procurement strategies and achieve better results over time.

Procurement Technologies and Their Effect on Supply Chain

Technological advancements have significantly transformed procurement and supply chain management, making them more efficient, transparent, and integrated. Technologies such as e-procurement platforms, artificial intelligence (AI), blockchain, and data analytics have reshaped the procurement landscape. According to a Verified Market Research report , the global procurement software market is projected to reach $9.5 billion worldwide by 2028, up significantly from $5.5 billion in 2020.

E-procurement platforms allow organisations to automate many aspects of the procurement process, from supplier selection to purchase order management. These platforms provide real-time data, improve transparency, and reduce the risk of errors. AI and machine learning algorithms enhance supplier selection by analysing large datasets to predict supplier performance and market trends. Blockchain technology offers secure and transparent contract management, ensuring that all transactions are traceable and tamper-proof.

These technologies streamline the procurement process and profoundly impact the supply chain. They enable better coordination between different entities in the supply chain, reduce lead times, and improve inventory management. As a result, organisations can respond more quickly to changes in demand, reduce costs, and improve overall supply chain resilience.

What Are the Supply Chain Entities?

The supply chain comprises various entities that work together to deliver products or services from the supplier to the end customer. Each entity plays a specific role in the supply chain, and their interactions determine the efficiency and effectiveness of the entire process.

1. Suppliers

Suppliers are the entities that provide the raw materials, components, or services needed to produce goods. They are the starting point of the supply chain, and their reliability and quality directly impact the entire process.

2. Manufacturers

Manufacturers take the raw materials or components suppliers provide and convert them into finished products. They play a critical role in adding value to the products and ensuring that they meet the required specifications and quality standards.

3. Distributors

Distributors act as intermediaries between manufacturers and retailers. They are responsible for storing and transporting products, ensuring that they reach the market efficiently. Distributors often manage large volumes of goods and play a key role in optimising inventory levels.

4. Retailers

Retailers are the entities that sell products directly to consumers. They are the final link in the supply chain and have direct contact with the end customer. Retailers’ performance is crucial as it influences customer satisfaction and the overall success of the supply chain.

5. Customers

Customers are the end users of the products or services. They drive demand in the supply chain and are the ultimate recipients of the goods produced. Understanding customer needs and preferences is essential for the entire supply chain to function effectively.

What is Supply Chain Management?

Supply chain management (SCM) is the process of overseeing and coordinating the entire supply chain to ensure that products are delivered to customers most efficiently and cost-effectively. It involves managing the flow of goods, information, and finances from suppliers to manufacturers, distributors, retailers, and finally to customers.

SCM encompasses various activities, including demand forecasting, inventory management, production planning, logistics, and customer service. Its goal is to optimise the supply chain, reduce costs, and enhance customer satisfaction. Effective SCM requires collaboration among all entities in the supply chain and the use of advanced technologies and data analytics to make informed decisions.

KPI | Meaning |

Order Fulfilment Cycle Time | Time taken to complete an order cycle. |

Inventory Turnover Ratio | Frequency of inventory replacement per year. |

Supply Chain Cost | Total cost of managing the supply chain. |

On-Time Delivery Rate | Percentage of deliveries made on schedule. |

Customer Order Accuracy | Percentage of orders filled without errors. |

Table: KPIs for Supply Chain Management

Why is Supply Chain Management Important?

Supply chain management (SCM) is essential to any business's operational efficiency and overall success. By coordinating and optimising the flow of goods, services, information, and finances across the entire supply chain, SCM helps organisations achieve their business goals, improve customer satisfaction, and maintain a competitive edge in the market. Here's a more detailed look at why SCM is so crucial:

1. Cost Reduction

Effective supply chain management enables organisations to reduce costs significantly across various areas of their operations. This cost reduction is achieved through several strategies:

- Optimising Inventory Levels: Proper SCM helps businesses maintain optimal inventory levels, reducing the costs associated with overstocking or stockouts. By accurately forecasting demand and managing inventory more efficiently, companies can minimise carrying costs, such as storage, insurance, and depreciation, while ensuring they have enough stock to meet customer demand.

- Efficient Transportation and Logistics: SCM involves planning the most cost-effective routes and transportation methods for delivering goods. By optimising logistics, companies can reduce transportation costs, fuel consumption, and shipping times. This not only lowers expenses but also enhances the reliability of deliveries, which can lead to better customer satisfaction.

- Improved Supplier Relationships: Effective SCM fosters strong supplier relationships, leading to better price, terms, and condition negotiation. By working closely with reliable suppliers, businesses can secure better deals, reduce procurement costs, and ensure a steady supply of high-quality materials or products.

- Lean Manufacturing and Waste Reduction: SCM often incorporates lean principles, which focus on eliminating waste in the production process. By streamlining operations and reducing excess, companies can lower production costs and increase profitability.

2. Improved Customer Satisfaction

According to LinkedIn, 57% of companies view supply chain management as a source of competitive advantage. Additionally, 70% believe that effective supply chains are crucial for delivering high-quality customer service. Here's how SCM plays a pivotal role in ensuring that customer needs are met consistently and efficiently:

- Timely Delivery: SCM ensures that products are delivered to customers on time, which is essential for maintaining trust and reliability. By coordinating the entire supply chain, from sourcing raw materials to final delivery, companies can meet deadlines and avoid delays that could lead to customer dissatisfaction.

- Product Quality: Effective SCM monitors product quality at every stage of the supply chain, from raw material procurement to manufacturing and distribution. By maintaining high standards and implementing quality control measures, companies can ensure that the products reaching customers are consistent and high quality, leading to fewer returns and complaints.

- Flexibility and Responsiveness: SCM enables companies to be more responsive to changes in customer demand. By managing inventory levels, production schedules, and logistics more effectively, businesses can quickly adjust to fluctuations in demand, whether scaling up for a seasonal surge or scaling down during slower periods. This flexibility helps provide better service to customers and enhances their overall experience.

- Enhanced Communication: SCM involves effective communication across all entities in the supply chain, ensuring that customer feedback and preferences are quickly relayed back to manufacturers and suppliers. This real-time communication allows faster adjustments to products or services based on customer needs, improving customer satisfaction.

3. Risk Management

Supply chains are inherently exposed to various risks, including supplier failures, natural disasters, political instability, and market fluctuations. SCM is crucial for identifying, assessing, and mitigating these risks to ensure continuity of operations. Here's how SCM contributes to risk management:

- Diversification of Suppliers: SCM encourages the diversification of the supplier base, which reduces dependency on a single supplier or region. Companies can mitigate the risk of supply chain disruptions caused by natural disasters, political unrest, or supplier bankruptcy by having multiple suppliers.

- Contingency Planning: Effective SCM involves developing contingency plans to address potential disruptions. These might include having backup suppliers, maintaining safety stock, or developing alternative transportation routes. These measures ensure that the supply chain remains resilient even in the face of unexpected challenges.

- Real-Time Monitoring and Analytics: Advanced SCM systems utilise real-time data and analytics to monitor the supply chain for any signs of disruption or inefficiency. This proactive approach allows companies to address issues before they escalate, reducing the potential impact on operations and customer service.

- Regulatory Compliance: SCM helps companies navigate the complex web of regulations governing international trade, labour practices, and environmental standards. By ensuring compliance with these regulations, businesses can avoid legal penalties, supply chain disruptions, and damage to their reputation.

4. Enhancing Competitiveness

In today’s globalised market, businesses must remain competitive to survive and thrive. SCM enhances competitiveness in several ways:

- Speed to Market: SCM enables companies to bring products to market faster by streamlining production, reducing lead times, and optimising logistics. This allows businesses to capitalise on new opportunities, respond quickly to market changes, and stay ahead of competitors.

- Cost Leadership: Through efficient SCM practices, companies can reduce costs and offer competitive pricing to customers. This cost advantage allows businesses to compete more effectively in price-sensitive markets while maintaining healthy profit margins.

- Innovation and Product Development: SCM facilitates collaboration between suppliers, manufacturers, and other stakeholders, fostering innovation and continuous improvement. By working closely with partners, companies can develop new products, improve existing ones, and respond to emerging trends more effectively.

- Customer-Centric Supply Chains: SCM allows companies to design supply chains tailored to meet specific customer needs, such as offering customised products, providing faster delivery options, or ensuring sustainable sourcing practices. This customer-centric approach enhances brand loyalty and gives companies a competitive edge.

5. Sustainability

Sustainability has become a key focus for businesses, driven by consumer demand, regulatory requirements, and the need to reduce environmental impact. SCM plays a vital role in promoting sustainability across the supply chain:

- Resource Optimization: SCM encourages the efficient use of resources, such as raw materials, energy, and water, throughout the supply chain. By minimising waste and optimising resource use, companies can reduce their environmental footprint and lower costs.

- Green Logistics: SCM incorporates sustainable logistics practices, such as optimising transportation routes to reduce fuel consumption, using energy-efficient vehicles, and adopting eco-friendly packaging. These practices help companies lower their carbon emissions and contribute to environmental conservation.

- Ethical Sourcing: SCM ensures that suppliers adhere to ethical and sustainable practices, such as fair labour conditions, responsible sourcing of raw materials, and compliance with environmental regulations. By promoting ethical sourcing, companies can build a more sustainable supply chain and enhance their corporate social responsibility (CSR) efforts.

- Circular Economy: SCM supports the transition to a circular economy, where products are designed for reuse, recycling, or refurbishment. By managing reverse logistics and product returns effectively, companies can reduce waste and extend the life cycle of their products.

In short, supply chain management is a cornerstone of modern business operations, providing numerous benefits that are essential for organisational success. From reducing costs and improving customer satisfaction to managing risks, enhancing competitiveness, and promoting sustainability, SCM enables companies to operate more efficiently and effectively in an increasingly complex and dynamic global marketplace. By investing in robust SCM practices, businesses can build resilient, responsive, and sustainable supply chains that drive long-term growth and profitability.

Five Steps of Supply Chain Management

Effective supply chain management involves a series of steps organisations follow to ensure that their supply chains are optimised and aligned with their business goals.

1. Planning

The first step in SCM is planning. This involves forecasting demand, determining the resources needed to meet that demand, and developing strategies to manage the flow of goods and information. Planning is crucial for aligning the supply chain with the organisation's objectives and ensuring all entities work towards common goals.

2. Sourcing

Sourcing involves selecting suppliers and negotiating contracts to obtain the materials, components, or services needed to produce goods. This step is closely related to procurement and requires a thorough evaluation of suppliers based on cost, quality, reliability, and sustainability.

3. Manufacturing

Manufacturing is the process of converting raw materials into finished products. This step includes production planning, quality control, and managing production processes to ensure that products meet specifications and are produced efficiently.

4. Delivery

Delivery involves distributing the finished products to customers. This step includes logistics, transportation, and warehousing. The goal is to ensure that products are delivered on time and in the right condition, minimising delays and disruptions.

5. Return

The final step in SCM is managing returns. This includes handling customer returns, recycling products, and managing reverse logistics. Efficient return management is essential for maintaining customer satisfaction and minimising the environmental impact of the supply chain.

Procurement vs. Supply Chain: Key Differences

While procurement and supply chain management are closely related, they serve different purposes and involve distinct activities.

1. Scope and Focus

Procurement is a specialised function that focuses primarily on the acquisition of goods and services needed by an organisation to carry out its operations. The scope of procurement is relatively narrow, encompassing activities such as sourcing, purchasing, and negotiating with suppliers. It ensures that the organisation obtains the necessary inputs—whether raw materials, components, or services—at the best possible cost, quality, and delivery terms.

Supply Chain Management , on the other hand, has a broader scope that encompasses the entire process of managing the flow of goods, services, information, and finances, from the initial sourcing of raw materials to the final delivery of products to customers. SCM involves multiple functions, including procurement, manufacturing, logistics, inventory management, and distribution. It optimises the entire supply chain to ensure efficiency, reduce costs, and meet customer demands.

In essence, while procurement is a key component of the supply chain, SCM covers the end-to-end process that links suppliers to customers, integrating all activities involved in creating and delivering products.

2. Activities and Processes

The activities involved in procurement and supply chain management differ significantly:

- Procurement Activities: Procurement involves specific tasks such as identifying needs, selecting suppliers, negotiating contracts, issuing purchase orders, and managing supplier relationships. It is primarily concerned with the transactional aspects of acquiring goods and services. Key processes include:

- Supplier Selection: Evaluating potential suppliers based on criteria like cost, quality, reliability, and compliance with standards.

- Contract Negotiation: Negotiating terms and conditions, including pricing, delivery schedules, payment terms, and service level agreements (SLAs).

- Purchase Order Management: Issuing and managing purchase orders, ensuring that orders are fulfilled according to the agreed-upon terms.

- Supplier Relationship Management: Maintaining ongoing relationships with suppliers to ensure continuous improvement, resolve issues, and negotiate better terms over time.

- Supply Chain Management Activities: SCM encompasses a broader range of activities that go beyond procurement. These include planning, sourcing, manufacturing, logistics, inventory management, distribution, and return management. Key processes include:

- Demand Planning: Forecasting customer demand and aligning production and inventory levels accordingly.

- Logistics and Distribution: Managing the transportation and warehousing of goods, optimising routes, and ensuring timely delivery to customers.

- Inventory Management: Balancing inventory levels to avoid stockouts or overstock situations, ensuring that products are available when needed without tying up excessive capital.

- Return Management: Handling product returns, reverse logistics, and recycling or disposal of products at the end of their life cycle.

While procurement is focused on securing the best deals for goods and services, SCM is concerned with the overall efficiency and effectiveness of the entire supply chain, from raw material sourcing to final product delivery.

3. Objectives and Goals

The primary objectives of procurement and SCM differ, reflecting their distinct roles within an organisation:

- Procurement Objectives: The main goal of procurement is to obtain goods and services at the best possible price, quality, and delivery terms. This involves:

- Cost Minimization: Reducing the cost of purchases through effective negotiation and supplier selection.

- Quality Assurance: Ensuring that the goods and services procured meet the required quality standards to support the organisation’s operations.

- Timely Delivery: Securing reliable delivery schedules that align with production or operational needs.

- Supplier Risk Management: Mitigating risks associated with supplier reliability, financial stability, and ethical and environmental standards compliance.

- Supply Chain Management Objectives: SCM aims to optimise the entire supply chain to enhance operational efficiency, reduce costs, and improve customer satisfaction. Its goals include:

- End-to-End Efficiency: Streamlining processes across the supply chain to minimise waste, reduce lead times, and lower costs.

- Customer Satisfaction: Ensuring that products are delivered on time, in the right quantity, and in the desired condition, meeting or exceeding customer expectations.

- Flexibility and Agility: Building a responsive supply chain that can quickly adapt to changes in demand, market conditions, or disruptions.

- Sustainability: Incorporating environmentally sustainable practices across the supply chain, such as reducing carbon emissions, optimising resource use, and promoting ethical sourcing.

While procurement focuses on securing the best inputs, SCM is concerned with the overall performance of the supply chain in delivering value to customers and the organisation.

Aspect | Procurement | Supply Chain Management |

Scope | Focuses on acquiring goods and services | Manages end-to-end supply process |

Primary Activities | Supplier selection, contract negotiation | Planning, logistics and inventory management |

Objectives | Cost, quality and supplier reliability | Efficiency, customer satisfaction and flexibility |

Role | Operational: Handles Purchasing activities | Strategic: Oversees entire supply network |

Key Focus | Transactional and contractual aspects | Integration and coordination across functions |

4. Strategic vs. Operational Role

Procurement and SCM also differ in terms of their strategic and operational roles within an organisation:

- Procurement’s Operational Role: Procurement is primarily an operational function, focused on executing day-to-day activities related to sourcing and purchasing. It involves tactical decisions, such as selecting suppliers, negotiating contracts, and managing purchase orders. While procurement can have strategic elements—such as developing long-term supplier partnerships—it is generally more concerned with the organisation's immediate needs.

- SCM’s Strategic Role: Supply chain management plays a more strategic role in the organisation. It involves long-term planning and coordination across multiple functions to ensure the supply chain supports the company’s overall business strategy. SCM requires a holistic view of the supply chain, considering factors such as market trends, customer expectations, and global supply chain dynamics. Strategic decisions in SCM might include optimising global supply networks, investing in technology to improve supply chain visibility, or implementing sustainable practices across the supply chain.

In this sense, while procurement deals with the "how" of acquiring goods and services, SCM deals with the "why" and "how" of moving those goods and services through the supply chain to deliver value to the end customer.

5. Interdependency and Interaction

Although procurement and SCM are distinct functions, they are highly interdependent and interact closely with each other:

- Procurement’s Impact on SCM: The decisions made in procurement directly affect the supply chain’s efficiency and effectiveness. For example, choosing a supplier with a shorter lead time can reduce inventory holding costs and improve responsiveness to customer demand. On the other hand, poor procurement decisions, such as selecting an unreliable supplier, can lead to supply chain disruptions, increased costs, and delays.

- SCM’s Influence on Procurement: Supply chain management provides the broader procurement context. SCM decisions, such as inventory management strategies, production planning, and logistics optimisation, influence procurement’s sourcing and supplier management approach. For instance, a just-in-time (JIT) inventory strategy may require procurement to work closely with suppliers to ensure timely deliveries, while a global supply chain strategy might necessitate sourcing from multiple regions to mitigate risks.

In practice, procurement and SCM must work collaboratively to ensure that the supply chain functions smoothly and aligns with the organisation’s strategic objectives. Effective communication and coordination between these two functions are essential for optimising overall supply chain performance.

In summary, while procurement and supply chain management are closely related, they serve different organisational roles. Procurement focuses on acquiring goods and services, emphasising cost, quality, and supplier relationships. In contrast, SCM takes a broader view, encompassing the entire process of moving goods from suppliers to customers, focusing on efficiency, customer satisfaction, and strategic alignment. Understanding the key differences between these functions is crucial for organisations looking to optimise their operations, reduce costs, and build a resilient and responsive supply chain. By leveraging the strengths of both procurement and SCM, businesses can achieve greater success and maintain a competitive edge in the market.

How Procurement Decisions Impact the Supply Chain and Vice Versa

Procurement decisions significantly impact the supply chain and vice versa. The quality of procurement decisions directly affects the supply chain's efficiency, cost, and reliability.

For example, selecting the right suppliers can lead to cost savings, improved product quality, and reduced lead times. Conversely, poor procurement decisions, such as choosing unreliable suppliers or failing to negotiate favourable terms, can lead to supply chain disruptions, increased costs, and customer dissatisfaction.

Conversely, supply chain management decisions also impact procurement. Decisions related to inventory management, production planning, and logistics can influence procurement strategies. A well-coordinated supply chain can lead to more accurate demand forecasts, better supplier relationships, and more efficient procurement processes.

Conclusion

Procurement and supply chain management are integral pillars supporting the success and sustainability of any organisation. While these functions operate in distinct spheres—procurement focusing on acquiring necessary goods and services and supply chain management overseeing the entire production and delivery flow—they are inherently interconnected. Together, they form the backbone of a business's operational strategy, contributing to its overall efficiency, cost-effectiveness, and competitive edge in the market. Understanding the nuances of both procurement and supply chain management, as well as their interactions, is crucial for optimising business operations, reducing costs, and ensuring that products and services reach customers in a timely and efficient manner.

By adopting advanced technologies like ERP systems, blockchain, and IoT, organisations can streamline procurement processes and enhance supply chain visibility, leading to more informed decision-making and improved operational performance. Strong, collaborative relationships with suppliers are also key to ensuring reliability and mitigating risks, thereby contributing to a resilient supply chain. Continuous process improvement through strategies like Lean and Six Sigma further ensures that the supply chain remains agile and responsive to market changes, helping organisations maintain a competitive advantage.

To deepen your understanding of these critical business functions and gain practical skills that can be applied to optimise your organisation’s supply chain, consider enrolling in our course "Supply Chain Management and Logistics." This comprehensive program covers the latest strategies, technologies, and best practices, equipping you with the knowledge and tools needed to build a robust and efficient supply chain that drives business success.