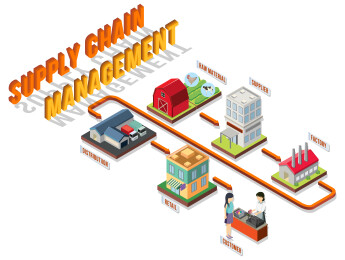

Navigating the intricate realm of modern business requires a multifaceted approach. One crucial aspect that often dictates the success or failure of an organisation is its purchasing strategies. These strategies are more than mere operational manoeuvres; they're the backbone of efficient resource allocation and building robust supplier relationships. In this comprehensive guide, we delve deep into the world of purchasing strategies, differentiating them from the purchasing process, exploring their benefits, and uncovering seven core strategies that have shaped successful enterprises worldwide.

Understanding the Essence of Purchasing Strategy

A purchasing strategy is a meticulously planned and well-executed approach that organisations adopt to procure goods and services in a way that aligns with their overall business goals. Unlike the purchasing process, which is a step-by-step sequence of activities leading to procurement, a purchasing strategy is a high-level framework that governs those activities. In essence, a purchasing strategy is the compass that guides companies through the vast ocean of supplier choices, negotiation tactics, and sourcing decisions.

Distinguishing Between Purchasing Process and Purchasing Strategy

To grasp the significance of purchasing strategies, it's vital to differentiate them from the purchasing process. The purchasing process encompasses the operational steps involved in obtaining goods or services, from identifying the need to payment. It's the nuts and bolts of procurement. In contrast, a purchasing strategy encompasses the overarching principles that guide these operational steps. While the process focuses on the 'how' of procurement, the strategy addresses the 'why' and 'what' of procurement decisions.

Aspect | Purchasing Process | Purchasing Strategy |

Definition | Sequential steps leading to procurement activities. | High-level framework aligning with business goals. |

Focus | Operational, detailing 'how' of procurement. | Strategic, addressing 'why' and 'what' of procurement. |

Level of Detail | Nuts and bolts of procurement tasks and activities. | Overarching principles guiding procurement decisions. |

Time Horizon | Short-term, immediate execution of procurement tasks. | Long-term, aligning with overall business objectives. |

Goal Alignment | Operational efficiency and task completion. | Business goals, risk mitigation, and innovation. |

The Crucial Role of Purchasing Strategies in Companies

Why do companies invest time, effort, and resources into formulating and implementing purchasing strategies? The answer lies in the potential benefits these strategies offer:

Cost Savings

One of the primary reasons companies invest time and resources in developing purchasing strategies is the potential for significant cost savings. A well-crafted strategy enables organisations to optimise their supplier relationships, negotiate favourable terms, and streamline procurement processes. By identifying areas where costs can be trimmed without compromising quality, companies implementing effective strategies can enhance their overall cost efficiency.

Risk Mitigation

Purchasing strategies act as a shield against the inherent risks associated with supply chain management. In a world where disruptions, market fluctuations, and unforeseen events are commonplace, these strategies provide a structured approach to identify, assess, and mitigate risks. By having contingency plans and risk mitigation strategies in place, companies can navigate through challenges, ensuring the continuity of their operations even in turbulent times.

Supplier Relationships

Building and maintaining strong, long-lasting relationships with suppliers are integral components of successful purchasing strategies. Strategic purchasing goes beyond transactional engagements; it fosters mutual trust, transparency, and collaboration. Companies that prioritise supplier relationships often find themselves in a position to negotiate favourable terms, access innovative solutions, and respond more effectively to market changes.

Innovation

Strategic engagement with suppliers creates an environment conducive to innovation. Through ongoing collaboration, companies can tap into the knowledge and expertise of their suppliers, leading to the exchange of innovative ideas, introduction of new technologies, and even collaborative product development. This not only enhances the company's product or service offerings but also positions them as industry leaders in terms of innovation.

Operational Efficiency

Well-defined purchasing strategies contribute significantly to operational efficiency. By streamlining procurement processes, minimising bureaucratic hurdles, and eliminating unnecessary intermediaries, companies can expedite the entire procurement cycle. This, in turn, reduces bottlenecks and delays in the supply chain, ensuring that products or services reach the market in a timely and efficient manner.

Market Advantage

In a competitive business landscape, companies with effective purchasing strategies gain a distinct market advantage. Accessing resources at better terms, whether through cost-effective supplier relationships or strategic sourcing decisions, allows these companies to offer products or services at competitive prices. This competitive edge can translate into increased market share and customer loyalty.

Sustainability

As global consciousness shifts towards sustainable practices, purchasing strategies become instrumental in supporting a company's sustainability goals. By selecting suppliers aligned with environmentally and socially responsible practices, organisations contribute to a more sustainable supply chain. This includes considerations such as fair labour practices, waste reduction, and carbon footprint, aligning the company with the expectations of environmentally conscious consumers.

In essence, the crucial role of purchasing strategies in companies extends far beyond the realm of procurement. These strategies are integral to the overall strategic vision of an organisation, influencing not only how goods and services are acquired but also how the company positions itself in the market, manages risks, and contributes to broader societal goals. As companies continue to evolve, the adaptability and effectiveness of their purchasing strategies will remain key indicators of their commitment to excellence and long-term success.

7 Widely Adopted Purchasing Strategies

Purchasing strategies are the backbone of procurement excellence, each catering to specific business goals and market dynamics. Let's dive deeper into these seven widely adopted strategies, exploring their intricacies and how they drive success:

1. Cost Leadership Strategy

The Cost Leadership Strategy is a staple for businesses aiming to achieve a competitive edge by offering products or services at the lowest possible cost. This strategy is all about efficiency and optimising economies of scale. Organisations implementing this strategy meticulously analyse their supply chain, identifying areas where costs can be trimmed without compromising quality.

Supplier Consolidation

A core facet of this strategy is consolidating suppliers to gain volume discounts and reduce administrative costs. By nurturing long-term relationships with a select group of suppliers, businesses can negotiate favourable terms, driving down costs.

Lean Procurement Processes

Efficiency is key. Companies employing the cost leadership strategy streamline their procurement processes, minimising paperwork, approvals, and unnecessary intermediaries. This not only cuts costs but also accelerates the entire procurement cycle.

2. Supplier Development Strategy

The Supplier Development Strategy is rooted in collaboration and long-term relationships. Instead of merely engaging with suppliers as transactional partners, companies adopting this strategy view them as extensions of their own teams, fostering mutual growth and innovation.

Continuous Improvement

In this strategy, companies work closely with suppliers to continually improve processes, products, and services. Regular feedback, joint problem-solving, and sharing best practices contribute to a symbiotic relationship where both parties benefit.

Investment in Suppliers

Organisations invest in their suppliers' capabilities through training programmes, technological support, and resource sharing. This not only enhances supplier performance but also aligns them with the company's goals and standards.

3. Just-in-Time Strategy

The Just-in-Time Strategy is a fine balance between cost optimisation and operational efficiency. It revolves around receiving goods only when needed to minimise inventory costs, storage space requirements, and waste.

Demand Forecasting

Accurate demand forecasting is the cornerstone of this strategy. Companies must possess a deep understanding of market trends and customer behaviour to ensure that they have the right quantity of products available precisely when needed.

Flexible Supplier Network

A responsive supplier network is crucial to execute this strategy successfully. Suppliers must be able to deliver goods promptly and reliably, aligning with the company's dynamic production schedule.

4. Outsourcing Strategy

The Outsourcing Strategy is the art of delegation, allowing companies to focus on their core competencies while entrusting non-core functions to specialised external suppliers.

Core Competency Focus

By outsourcing non-core functions, companies can concentrate their resources on activities that directly contribute to their competitive advantage, driving innovation and differentiation.

Risk and Benefit Analysis

While outsourcing can reduce costs and enhance efficiency, it's essential to carefully evaluate potential risks, such as loss of control and quality issues. Selecting the right outsourcing partners and maintaining clear communication are vital.

5. Global Sourcing Strategy

The Global Sourcing Strategy capitalises on the interconnectedness of the modern world. Businesses source goods and services from various countries to leverage cost advantages, access unique resources, and expand their reach.

Cultural Understanding

Engaging with suppliers from diverse cultures requires sensitivity and understanding. Effective cross-cultural communication and negotiation skills are essential to navigate cultural nuances and build successful partnerships.

Supply Chain Complexity

While global sourcing can yield cost savings, it also introduces complexities related to logistics, customs regulations, and geopolitical factors. Companies must carefully manage these complexities to avoid disruptions.

6. Risk Diversification Strategy

The Risk Diversification Strategy is all about resilience. By spreading procurement across multiple suppliers, companies reduce the impact of supply chain disruptions, ensuring business continuity in the face of unforeseen events.

Supplier Redundancy

This strategy involves having backup suppliers ready to step in if the primary supplier faces issues. While it adds to procurement complexity, it provides a safety net in times of crisis.

Supply Chain Mapping

To effectively diversify risk, companies need a clear picture of their supply chain. This includes understanding suppliers' locations, dependencies, and potential vulnerabilities.

7. Sustainable Procurement Strategy

The Sustainable Procurement Strategy aligns with a growing global emphasis on environmental and social responsibility. Companies adopting this strategy prioritise suppliers with ethical practices and sustainable operations.

Ethical Supplier Selection

Businesses employing this strategy carefully vet suppliers to ensure they adhere to environmentally friendly and socially responsible practices. This includes factors such as fair labour practices, waste reduction, and carbon footprint.

Corporate Social Responsibility

Sustainable procurement contributes to a company's overall corporate social responsibility initiatives, enhancing its reputation and resonating with environmentally conscious consumers.

These seven widely adopted purchasing strategies showcase the versatility and adaptability required in modern business. Organisations must carefully select and tailor these strategies to align with their specific goals, market dynamics, and industry trends. The effectiveness of these strategies lies not only in their individual application but also in their integration into a cohesive and comprehensive approach that guides the entire procurement process, contributing to the overall success of the organisation.

Digital Transformation in Procurement

In an era where technological advancements reshape industries, digital transformation has become a cornerstone for business evolution. The procurement landscape is no exception, as organisations increasingly leverage cutting-edge technologies to enhance efficiency, reduce costs, and make more informed decisions. Let’s explore the realm of digital transformation in procurement, shedding light on how businesses are embracing technology to transform their procurement processes and gain a competitive edge.

a) Understanding Digital Transformation in Procurement

Digital transformation in procurement involves the integration of digital technologies to streamline and optimise the end-to-end procurement process. This goes beyond traditional methods, incorporating artificial intelligence (AI), machine learning (ML), data analytics, and automation to create a more agile and data-driven procurement function.

b) Benefits of Digital Transformation

Real-time Insights

Digital transformation provides real-time visibility into procurement activities. With advanced analytics, organisations can gain insights into spending patterns, supplier performance, and overall procurement efficiency. This real-time data empowers decision-makers to make informed choices promptly.

Predictive Analytics

The integration of predictive analytics allows organisations to anticipate market trends, identify potential risks, and optimise procurement strategies. By analysing historical data and market indicators, businesses can proactively adjust their procurement approach for better outcomes.

Cost Reduction

Automation of routine tasks and intelligent data analysis contribute to cost reduction. Digital procurement solutions streamline processes, minimise manual intervention, and identify cost-saving opportunities, allowing organisations to optimise their spending and improve the bottom line.

Enhanced Supplier Management

Digital platforms enable more efficient supplier management. Through data-driven insights, organisations can assess supplier performance, identify potential risks, and make strategic decisions regarding supplier relationships. This, in turn, contributes to the development of a more resilient and collaborative supply chain.

Improved Compliance

Digital transformation ensures that procurement processes adhere to regulatory and compliance standards. Automation helps in tracking and managing compliance requirements, reducing the risk of errors and non-compliance, which could lead to legal or financial repercussions.

c) AI and Machine Learning in Procurement

Demand Forecasting

AI and machine learning algorithms can analyse historical data and market trends to enhance demand forecasting accuracy. This is particularly beneficial in aligning procurement activities with actual market needs, preventing overstock or stockouts.

Supplier Risk Management

Machine learning models can assess various factors, such as financial stability and geopolitical risks, to predict potential issues with suppliers. This proactive approach enables organisations to mitigate risks before they impact the supply chain.

Intelligent Procurement Automation

AI-driven automation enhances the efficiency of routine procurement tasks. Chatbots, for instance, can handle queries, while automated workflows can streamline the approval process. This not only accelerates procurement cycles but also frees up human resources for more strategic activities.

d) Blockchain Integration

Enhanced Transparency

Blockchain technology ensures transparency and traceability in procurement. By creating an immutable ledger of transactions, organisations can track the journey of products from manufacturers to end-users. This transparency minimises the risk of fraud and ensures the integrity of the supply chain.

Smart Contracts

Smart contracts, powered by blockchain, automate and self-execute contractual agreements. In procurement, this means that payment terms, delivery schedules, and other contract-related conditions can be programmed, reducing the need for manual oversight and intervention.

Reduced Counterfeiting

Blockchain's secure and decentralised nature makes it an effective tool in reducing counterfeiting. By verifying the authenticity of products at each stage of the supply chain, organisations can ensure that they receive genuine goods from suppliers.

e) Challenges and Considerations

Integration Complexity

The integration of digital technologies can be complex, requiring careful planning and consideration. Organisations must assess their existing systems, invest in compatible technologies, and ensure a seamless integration process to avoid disruptions.

Data Security

With increased reliance on digital platforms, data security becomes paramount. Organisations must implement robust cybersecurity measures to safeguard sensitive procurement data and prevent unauthorised access or data breaches.

Employee Training

The successful implementation of digital transformation requires a workforce that is adept at using new technologies. Organisations must invest in training programs to ensure that employees can leverage digital tools effectively and maximise the benefits of the transformation.

f) The Future of Digital Transformation in Procurement

Emerging Technologies

The future of digital transformation in procurement is likely to witness the integration of even more advanced technologies. Augmented reality (AR), the Internet of Things (IoT), and advanced analytics will play pivotal roles in further enhancing procurement processes.

Collaboration Platforms

Digital transformation will foster increased collaboration between buyers and suppliers. Cloud-based collaboration platforms will facilitate real-time communication, document sharing, and collaborative decision-making, leading to more agile and responsive supply chains.

Eco-friendly Practices

As sustainability becomes a central concern, digital transformation in procurement will also focus on eco-friendly practices. Technologies will be leveraged to track and reduce the environmental impact of procurement activities, aligning with broader corporate social responsibility goals.

In short, the digital transformation of procurement is a transformative journey that holds immense potential for organisations seeking to optimise their procurement processes. By embracing advanced technologies, businesses can gain a competitive advantage, enhance operational efficiency, and adapt to the ever-evolving demands of the modern market. The integration of AI, machine learning, blockchain, and other digital tools represents a strategic investment that positions organisations at the forefront of innovation and excellence in procurement practices.

Conclusion

In the dynamic landscape of business, purchasing strategies play a pivotal role in shaping an organisation's success. Beyond the surface-level mechanics of procurement, these strategies provide a compass that guides companies towards their goals, whether it's minimising costs, fostering innovation, or ensuring sustainability. By understanding the essence of purchasing strategies, differentiating them from the purchasing process, and exploring the array of strategies available, businesses can position themselves as strategic players in a competitive market. As organisations continue to evolve, so too will their purchasing strategies, serving as a testament to their adaptability and commitment to excellence.

Ready to take your procurement expertise to the next level? Enrol in our course, ‘Selecting the Right Supplier & Creating Effective Purchasing Processes,’ where you'll gain practical insights and strategies to optimise your procurement practices and drive tangible results. Don't just learn about procurement – master it.

Frequently Asked Questions(FAQ)

What is the difference between a purchasing strategy and a purchasing process?

A purchasing strategy is a high-level framework guiding procurement decisions aligned with business goals, while a purchasing process is a sequence of operational steps leading to procurement. The strategy sets the overarching principles, addressing the 'why' and 'what' of procurement, while the process focuses on the 'how'. This differentiation ensures that while the process efficiently executes procurement tasks, the strategy ensures those tasks align with broader organisational objectives.

Why do companies need purchasing strategies?

Purchasing strategies offer cost savings, risk mitigation, supplier relationship building, innovation, operational efficiency, market advantage, and sustainability, aligning procurement with business objectives. Beyond cost reduction, these strategies foster resilience, adaptability, and ethical practices, contributing to a company's long-term success and competitive positioning in the market.

How do I choose the right purchasing strategy for my company?

To choose the right purchasing strategy, assess your company's goals, market dynamics, resources, and risk tolerance. Select a strategy that aligns with your priorities and strengths, while considering the potential challenges and benefits. A comprehensive understanding of your organisation's unique context and a strategic approach to aligning procurement with overarching business objectives is key to selecting the most effective strategy.

What challenges might arise when implementing a global sourcing strategy?

Global sourcing can introduce complexities like logistics, cultural differences, regulatory challenges, and geopolitical risks. Mitigate these challenges by conducting thorough research on potential suppliers, establishing robust relationships, and developing contingency plans. Proactive risk management, clear communication, and a strategic approach to navigating the intricacies of global markets are essential to the successful implementation of a global sourcing strategy.

How does a sustainable procurement strategy benefit a company beyond environmental concerns?

Apart from addressing environmental impact, a sustainable procurement strategy enhances a company's reputation, resonates with socially conscious consumers, contributes to corporate social responsibility initiatives, and fosters long-term supplier relationships. This strategy not only aligns with ethical business practices but also positions the company as a responsible and conscientious player in the market, appealing to a growing demographic of environmentally and socially conscious consumers.