- Table of Contents

- Introduction

- What Is a Supply Chain Control Tower?

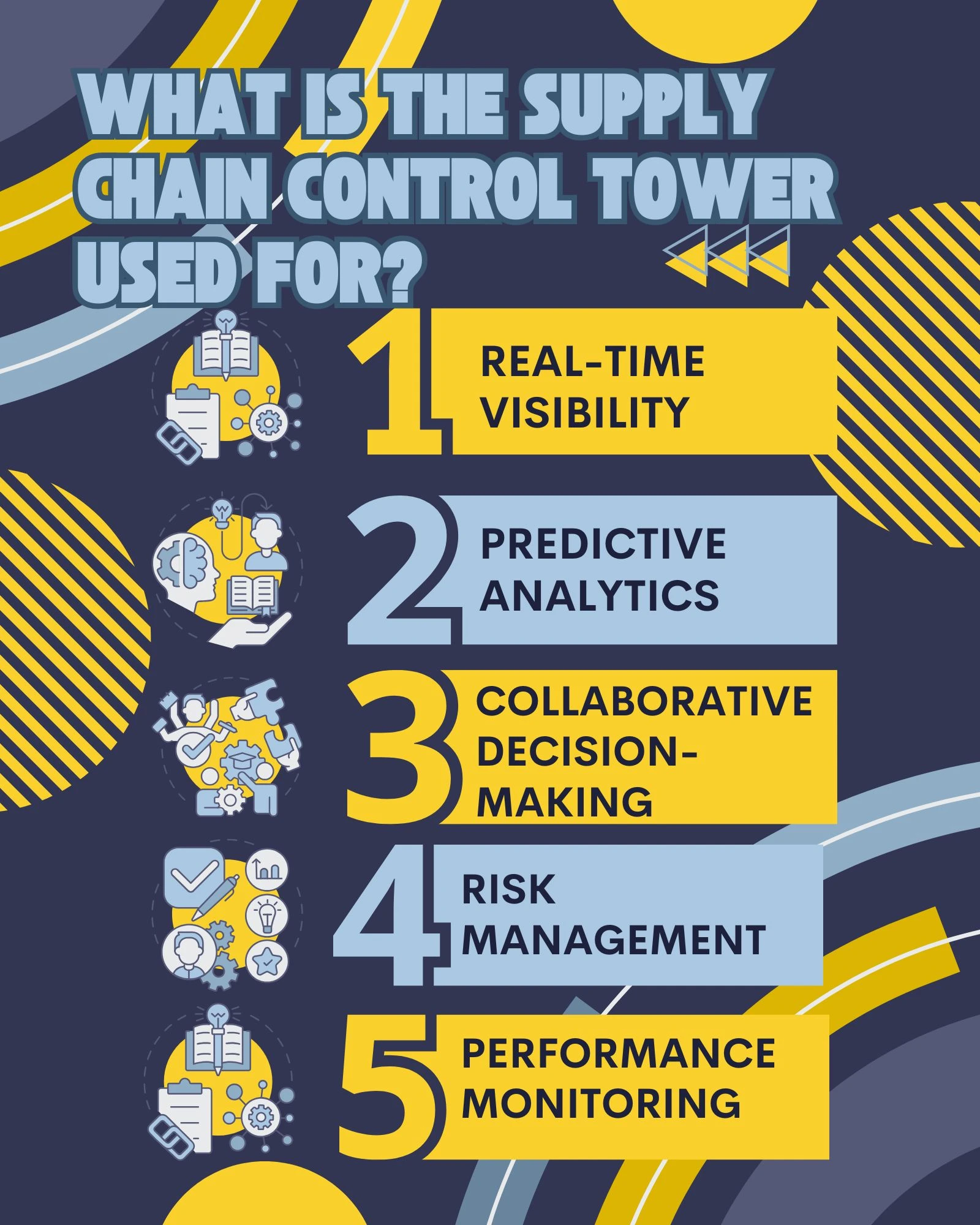

- What Is the Supply Chain Control Tower Used For?

- Real-Time Visibility

- Predictive Analytics

- Collaborative Decision-Making

- Risk Management

- Performance Monitoring

- Why Is the Supply Chain Control Tower Important?

- Enhanced Agility

- Cost Optimisation

- Customer Satisfaction

- Risk Mitigation

- Continuous Improvement

- How to Deploy a Supply Chain Control Tower

- 1. Assessment and Planning

- 2. Data Integration and Connectivity

- 3. Technology Selection

- 4. Collaboration and Training

- 5. Pilot Implementation

- 6. Continuous Improvement and Optimisation

- Empowering Supply Chain Technology Leaders with the Control Tower

- 1. Cultural Transformation

- 2. Investment in Technology

- 3. Data Management and Analytics

- 4. AI and Machine Learning

- 5. Change Management

- The Human Element in Supply Chain Control Towers

- Conclusion

Introduction

In the rapidly evolving world of modern business, supply chains have morphed into intricate and interconnected networks. As the global marketplace expands and customer expectations soar, mastery over supply chain operations has become necessary. Enter the Supply Chain Control Tower - a game-changing concept that catalyses change, enabling organisations to optimise their supply chain processes and elevate overall performance. In this comprehensive blog post, we will take an in-depth journey into the realm of Supply Chain Control Towers. We'll delve into their definition, explore their multifaceted uses, underline their importance, outline deployment strategies, and provide valuable insights for supply chain technology leaders to harness their full potential.

What Is a Supply Chain Control Tower?

Imagine a central hub that offers real-time visibility, complete transparency, and efficient orchestration of every aspect of your supply chain. This is precisely what a Supply Chain Control Tower represents – a digital command centre that provides a holistic view of an organisation's supply chain operations. This centralised platform consolidates data from numerous sources, including suppliers, manufacturers, logistics providers, and IoT-enabled devices, into a single, cohesive interface. By employing advanced analytics and artificial intelligence (AI), the control tower transforms the deluge of supply chain data into actionable insights.

In essence, the Supply Chain Control Tower functions as the brain of the supply chain, enabling businesses to monitor and manage their end-to-end processes efficiently. It acts as a strategic enabler, fostering collaboration, enhancing efficiency, and mitigating risks within the supply chain ecosystem.

Feature | Description |

Real-time Visibility | Offers instantaneous insight into all supply chain activities. |

Predictive Analytics | Utilises historical and real-time data for predictive insights and proactive measures. |

Collaborative Decision-Making | Facilitates seamless collaboration among departments and external partners. |

Risk Management | Identifies and assesses potential risks to develop mitigation strategies. |

Performance Monitoring | Tracks supply chain performance against predefined KPIs. |

Table 1: Key Features of a Supply Chain Control Tower

What Is the Supply Chain Control Tower Used For?

The applications of a Supply Chain Control Tower are vast and varied, extending far beyond simple data visualisation. Let's explore some of the key uses:

Real-Time Visibility

The control tower provides real-time visibility into every aspect of the supply chain, from procurement to delivery. This level of transparency empowers stakeholders to make informed decisions promptly.

Predictive Analytics

The control tower can offer predictive insights, such as demand forecasting, inventory optimisation, and potential disruptions by analysing historical and real-time data. These foresights enable proactive measures, reducing the impact of disruptions and enhancing overall agility.

Collaborative Decision-Making

A control tower facilitates seamless collaboration among various departments and external partners. With shared visibility, teams can work together to address issues promptly and align their actions with the broader supply chain goals.

Risk Management

Supply chains are susceptible to risks such as geopolitical events, natural disasters, and supplier disruptions. The control tower helps identify and assess these risks, allowing organisations to develop risk mitigation strategies.

Performance Monitoring

Organisations can track the performance of their supply chain operations against predefined KPIs. Any deviations can be quickly identified, and corrective actions can be taken to optimise performance.

Why Is the Supply Chain Control Tower Important?

A Supply Chain Control Tower is not merely a technological tool but a business-critical asset. Its importance extends across various facets of modern business, and its role cannot be overstated. Here, we dive deeper into the significance of Supply Chain Control Towers:

Enhanced Agility

In today's fast-paced business landscape, agility is paramount. Markets are volatile, customer demands fluctuate, and unforeseen disruptions are commonplace. A Control Tower equips organisations with the agility to respond rapidly and intelligently to these challenges. Real-time visibility into the supply chain means that decision-makers can promptly spot emerging issues and make data-driven decisions. Whether it's adjusting production schedules, rerouting shipments, or reallocating resources, the control tower empowers organisations to adapt swiftly to changing circumstances. This agility is a competitive advantage, enabling businesses to stay ahead of the curve and outmanoeuvre rivals.

Cost Optimisation

Cost control is a perennial concern for businesses, and the supply chain is often a significant cost centre. The Control Tower can be a powerful ally in optimising costs without sacrificing performance. By analysing data from across the supply chain, it identifies opportunities for efficiency gains. For example, it can optimise inventory levels, reducing carrying costs while ensuring products are readily available. It can optimise transportation routes, reducing fuel consumption and transportation expenses. It can also optimise production schedules, reducing overtime and waste. These optimisations collectively result in substantial cost reductions, improving the bottom line while maintaining or even enhancing service levels.

Customer Satisfaction

In the e-commerce and instant gratification age, meeting customer expectations is non-negotiable. A well-managed supply chain, facilitated by the Control Tower, is instrumental in achieving this. Customers demand timely, accurate, and transparent deliveries. The Control Tower provides the means to meet these demands. It ensures that products are in stock and ready for dispatch, minimising stockouts and backorders. It optimises transportation and logistics, ensuring on-time deliveries. Furthermore, it provides real-time tracking and communication, so customers can track their orders and receive updates, enhancing their experience. High levels of customer satisfaction translate into repeat business, positive reviews, and brand loyalty.

Risk Mitigation

In today's interconnected world, supply chains are vulnerable to many risks. These include geopolitical events, natural disasters, economic downturns, and supplier disruptions. The Control Tower is a risk management tool that helps organisations identify, assess, and mitigate these risks. It provides real-time visibility into potential disruptions, allowing organisations to take proactive measures. For example, suppose a supplier in a geographically sensitive area experiences delays due to a natural disaster. In that case, the Control Tower can suggest alternative suppliers or transportation routes to minimise the impact on operations. This risk mitigation reduces the likelihood of supply chain disruptions and enhances an organisation's resilience in the face of adversity.

Continuous Improvement

In the pursuit of excellence, continuous improvement is a fundamental principle. The Control Tower acts as an enabler of continuous improvement by providing data-driven insights and performance metrics. It offers detailed analytics that reveal trends, patterns, and areas for enhancement within the supply chain. Organisations can identify bottlenecks, process inefficiencies, and areas of excess cost. Armed with this information, they can implement targeted improvements. For instance, if the analytics highlight excessive lead times in procurement, the organisation can renegotiate supplier contracts or seek more efficient sourcing options. This commitment to ongoing improvement ensures that the supply chain remains agile, efficient, and aligned with business objectives.

In summary, the importance of a Supply Chain Control Tower cannot be overstated. It bolsters organisational agility, optimises costs, delights customers, mitigates risks, and fosters a culture of continuous improvement. It's a technology investment and a strategic imperative for modern businesses seeking to thrive in a competitive and volatile marketplace.

How to Deploy a Supply Chain Control Tower

Deploying a Supply Chain Control Tower is a strategic initiative that demands meticulous planning, effective implementation, and seamless integration into an organisation's operations. Here are the key steps to deploy a control tower effectively:

1. Assessment and Planning

Begin with a comprehensive assessment of your existing supply chain processes and technology infrastructure. This step is crucial as it helps you identify pain points, set clear objectives, and define the desired outcomes. Collaborate with key stakeholders, including supply chain managers, IT professionals, and executives, to ensure alignment with organisational goals. Consider the following aspects:

Identify Pain Points: Analyse the current state of your supply chain and pinpoint areas for improvement. These could include issues like long lead times, excessive inventory, unreliable suppliers, or poor visibility.

Set Objectives: Define what you aim to achieve with the Control Tower. Is it improved visibility, cost reduction, enhanced customer service, or risk mitigation? Establish clear, measurable objectives.

Resource Allocation: Determine the resources required for the project, including budget, personnel, and technology investments.

Key Performance Indicators (KPIs): Develop a set of KPIs that will help measure the success of your Control Tower implementation. These KPIs should align with your objectives.

Timelines: Create a timeline that outlines the implementation phases and sets realistic deadlines for each project stage.

KPI | Significance |

Reduced Lead Times | Indicates improved supply chain efficiency and agility, enabling faster response to customer needs |

Optimised Inventory Levels | Demonstrates better cost control by minimising carrying costs while ensuring product availability |

Cost Savings | Reflects reduced operational expenses due to streamlined processes and improved resource allocation |

On-time Deliveries | Highlights improved customer service, reliability and fulfilment of delivery commitments |

Customer Satisfaction | Indicates enhanced customer experience, leading to increased loyalty, repeat business and referrals |

Table 2: KPIs to consider when measuring the success of control tower implementation

2. Data Integration and Connectivity

Data is the lifeblood of a Supply Chain Control Tower. Ensure seamless integration of data from internal systems and external partners. This step requires a well-thought-out data strategy:

Data Sources: Identify all relevant data sources, both internal (ERP systems, warehouse management systems, etc.) and external (supplier data, market data, etc.). Ensure that data can be collected in real-time or at frequent intervals.

Data Standards: Establish data standards and protocols to ensure consistency and compatibility across all data sources.

Data Quality: Implement data cleansing and validation processes to maintain data accuracy and reliability.

Data Security: Pay special attention to data security and compliance with data protection regulations, particularly when dealing with sensitive customer or supplier information.

3. Technology Selection

Choosing the right technology solution is critical to the success of your Control Tower implementation. Look for a solution that aligns with your business requirements and growth plans:

Advanced Analytics: Seek a Control Tower solution that offers advanced analytics capabilities. This includes predictive analytics, machine learning, and data visualisation tools to extract actionable insights from your data.

User-Friendly Interface: Ensure that the Control Tower has an intuitive and user-friendly interface. This will promote adoption and make it easier for users to leverage its capabilities.

Scalability: Consider your organisation's growth potential. Choose a Control Tower solution that can scale as your supply chain operations expand.

Integration: Confirm that the Control Tower can seamlessly integrate with your existing systems, such as ERP, CRM, and transportation management systems.

4. Collaboration and Training

Implementing a Control Tower involves more than just technology; it's a cultural shift within the organisation. Collaboration and training are key:

Educate Stakeholders: Conduct training sessions and workshops to educate all stakeholders about the Control Tower's capabilities and benefits. Ensure that teams understand how to interpret and act upon the insights provided by the Control Tower.

Foster a Collaborative Culture: Promote a culture of collaboration and shared accountability. Encourage cross-functional teams to work together, using the Control Tower as a common platform for decision-making.

Change Management: Develop a comprehensive change management plan to manage the organisational shift that comes with a Control Tower implementation. Address resistance to change and ensure that employees embrace the new working method.

5. Pilot Implementation

Before rolling out the Control Tower on a full scale, conduct a pilot implementation to validate its effectiveness and identify any challenges or adjustments needed:

Select a Representative Subset: Choose a representative subset of your supply chain operations for the pilot phase. This could be a specific product line, region, or distribution centre.

Measure and Analyse Results: Implement the Control Tower in the selected subset and closely monitor its performance. Assess its impact on key metrics and KPIs.

Gather Feedback: Encourage feedback from users involved in the pilot. Their insights can help fine-tune the Control Tower's functionality and user experience.

Iterate and Improve: Based on the feedback and results from the pilot, adjust the implementation plan and technology configuration as needed.

Once the pilot phase is successful, you can proceed with a full-scale deployment of the Control Tower across your entire supply chain operations.

6. Continuous Improvement and Optimisation

A Supply Chain Control Tower is not a one-and-done project; it's an ongoing journey. After full deployment, commit to continuous improvement:

Regular Reviews: Schedule regular reviews to assess the Control Tower's performance and its alignment with your objectives. Use the insights generated by the Control Tower to identify opportunities for further optimisation.

Feedback Loop: Maintain an open feedback loop with users and stakeholders. Their input can help uncover emerging challenges or evolving requirements.

Stay Current: Keep abreast of advancements in supply chain technology. Periodically evaluate whether your Control Tower needs updates or enhancements to remain effective in a changing landscape.

Benchmarking: Compare your supply chain's performance against industry benchmarks to identify areas where you can excel.

In summary, deploying a Supply Chain Control Tower is a strategic undertaking that requires meticulous planning, stakeholder engagement, and technology integration. It's a dynamic process that should be adapted to your organisation's unique needs and objectives. By following these steps and embracing a culture of continuous improvement, you can maximise the benefits of a Control Tower and stay ahead in the ever-evolving world of supply chain management.

Empowering Supply Chain Technology Leaders with the Control Tower

Supply chain technology leaders play a pivotal role in unlocking the full potential of a Supply Chain Control Tower. Their expertise and leadership are critical in ensuring the Control Tower is effectively implemented, leveraged to its maximum capacity, and seamlessly integrated into the organisation's operations. Here, we delve deeper into the key strategies for empowering these leaders:

1. Cultural Transformation

Supply chain technology leaders must champion a cultural transformation within the organisation. This transformation involves instilling a mindset of innovation, collaboration, and data-driven decision-making. Here's how:

Advocating Innovation: Encourage teams to embrace innovative approaches in supply chain management. Emphasise the importance of staying up-to-date with emerging technologies and trends, such as AI, blockchain, and IoT.

Promoting Collaboration: Foster a collaborative culture where cross-functional teams work together seamlessly. The Control Tower should serve as a central platform for communication and information sharing among different departments.

Data-Driven Decision-Making: Stress the significance of data-driven decision-making. Encourage teams to rely on the insights generated by the Control Tower when making critical supply chain decisions.

Leading by Example: Supply chain technology leaders should set an example by actively participating in collaborative efforts and demonstrating their commitment to data-driven approaches.

2. Investment in Technology

Supply chain technology leaders need to stay at the forefront of technological advancements to harness the full potential of a Control Tower. Here's how they can achieve this:

Continuous Learning: Invest in continuous learning and professional development for yourself and your team. Stay updated with the latest supply chain management trends, tools, and technologies.

Technology Evaluation: Regularly evaluate the technology landscape for solutions that can complement and enhance your Control Tower. Assess how emerging technologies, such as AI and machine learning, can be integrated for greater insights and automation.

Vendor Partnerships: Develop strategic partnerships with technology vendors and solution providers. Leverage their expertise to ensure your Control Tower remains cutting-edge and meets evolving business requirements.

3. Data Management and Analytics

Effective data management and analytics are pivotal in extracting meaningful insights from the vast amount of supply chain data processed by the Control Tower:

Data Governance: Establish robust data governance practices to ensure data quality, consistency, and compliance. Define data ownership, access controls, and data lifecycle management.

Advanced Analytics Tools: Invest in powerful analytics tools that can handle complex data processing and visualisation. These tools should facilitate in-depth analysis of supply chain performance and help identify areas for improvement.

Predictive Analytics: Implement predictive analytics models within the Control Tower to anticipate supply chain disruptions, demand fluctuations, and inventory optimisation opportunities.

Data Integration: Ensure that data from various sources is seamlessly integrated into the Control Tower. Implement data connectors and ETL (Extract, Transform, Load) processes to maintain data flow in real-time.

4. AI and Machine Learning

AI and machine learning technologies can greatly enhance the capabilities of a Control Tower. Supply chain technology leaders should explore these technologies to unlock their full potential:

Pattern Recognition: AI can identify patterns in historical and real-time data that may not be apparent through traditional analysis. It can recognise trends, anomalies, and correlations that inform better decision-making.

Predictive Insights: Machine learning algorithms can accurately predict supply chain disruptions, demand changes, and inventory needs. These predictive insights enable proactive measures.

Automation: AI-powered automation can streamline routine supply chain tasks like ordering and inventory management. This reduces manual workload and frees up resources for strategic decision-making.

Continuous Improvement: Use AI and machine learning to optimise supply chain operations continually. These technologies adapt to changing conditions and continuously seek the most efficient paths and strategies.

5. Change Management

Implementing a Control Tower requires organisational change. Supply chain technology leaders should take a structured approach to change management:

Clear Communication: Communicate the Control Tower implementation's goals, benefits, and expected outcomes clearly to all stakeholders. Proactively address any concerns or resistance to change.

Training and Skill Development: Provide training and skill development opportunities for employees to ensure they can use the Control Tower effectively. This includes understanding data analytics, interpreting insights, and taking action based on Control Tower recommendations.

Monitoring Progress: Continuously monitor the progress of the Control Tower implementation, identify any bottlenecks, and adjust strategies as needed. Keep the organisation informed about the positive impact and improvements achieved through the Control Tower.

The Human Element in Supply Chain Control Towers

While technology is at the forefront of supply chain control towers, the human element remains indispensable. Skilled professionals are needed to interpret data, make strategic decisions, and drive collaboration among teams and partners. As control towers evolve, the role of supply chain professionals will also change. They must develop new skills, including data analytics, AI understanding, and change management. Investing in the training and development of the workforce is crucial to maximise the effectiveness of supply chain control towers and ensure their successful integration into the organisation's culture.

Conclusion

In conclusion, a Supply Chain Control Tower is a potent catalyst for change, empowering businesses to optimise their supply chain operations and enhance overall performance. The control tower empowers organisations to navigate uncertainties, reduce costs, and delight customers by providing real-time visibility, predictive insights, and fostering collaboration. Supply chain technology leaders play a pivotal role in realising the full potential of a control tower by driving cultural transformation, investing in technology, and embracing data-driven decision-making. With a well-planned implementation and continuous improvement efforts, organisations can leverage the control tower as a strategic enabler to thrive in the ever-evolving world of supply chain management.

To further equip supply chain technology leaders with the knowledge and skills to harness the benefits of control towers, we invite you to explore our comprehensive course, ‘Supply Chain Management and Logistics’. This course empowers you with the latest industry insights, best practices, and practical tools, enabling you to take charge of your supply chain's success in this dynamic business landscape. Enrol today and lead your organisation towards supply chain excellence.