- Table of Contents

- What Is the HAZOP Study?

- The Importance of HAZOP Analysis

- Early Hazard Identification

- Risk Reduction and Cost Savings

- Compliance with Regulatory Standards

- Enhanced Process Understanding

- Preventing Catastrophic Incidents

- Creating a Safety Culture

- Continuous Improvement

- The HAZOP Study Process

- 1- Formation of the Study Team

- 2- Define the Study Objectives

- 3- Selection of Study Nodes

- 4- Application of Guidewords

- 5- Brainstorming and Identifying Deviations

- 6- Risk Assessment

- Results of a HAZOP Study

- Identification of Potential Hazards

- Operability Enhancements

- Recommendations for Risk Reduction

- Documentation of Findings

- The Role of Labelling in HAZOP

- Clarity Through Accurate Labelling

- Facilitating Smooth Communication

- Facilitating Comprehensive Understanding

- Preventing Overlooking Potential Hazards

- Promoting Efficiency and Thoroughness

- HAZOP in the Oil and Gas Industry

- Exploration and Production

- Refining and Processing

- Transportation

- The Future of the HAZOP Method

- Integration of Artificial Intelligence (AI) and Machine Learning (ML):

- Virtual Reality (VR) Simulations for Enhanced Training:

- Enhanced Data Visualisation and Collaboration Tools:

- Focus on Sustainability and Environmental Impact:

- Continued Training and Professional Development:

- In Conclusion

Introduction

Ensuring safety is paramount in a world driven by industrial progress and innovation. Hazard and Operability (HAZOP) study emerges as a crucial tool in safeguarding complex processes within industries, such as oil and gas. This systematic approach identifies potential hazards and optimises operability, leading to safer and more efficient operations. In this blog post, we will delve into the methodology of the HAZOP study, its significance, and its role in different sectors, particularly the oil and gas industry.

What Is the HAZOP Study?

The Hazard and Operability study, commonly known as HAZOP, is a structured and systematic analysis that evaluates potential hazards and operability issues within a process. Developed in the late 1960s by ICI (Imperial Chemical Industries) in the United Kingdom, HAZOP has since become a widely adopted risk assessment technique in various industries, including chemical, pharmaceutical, nuclear, and oil and gas.

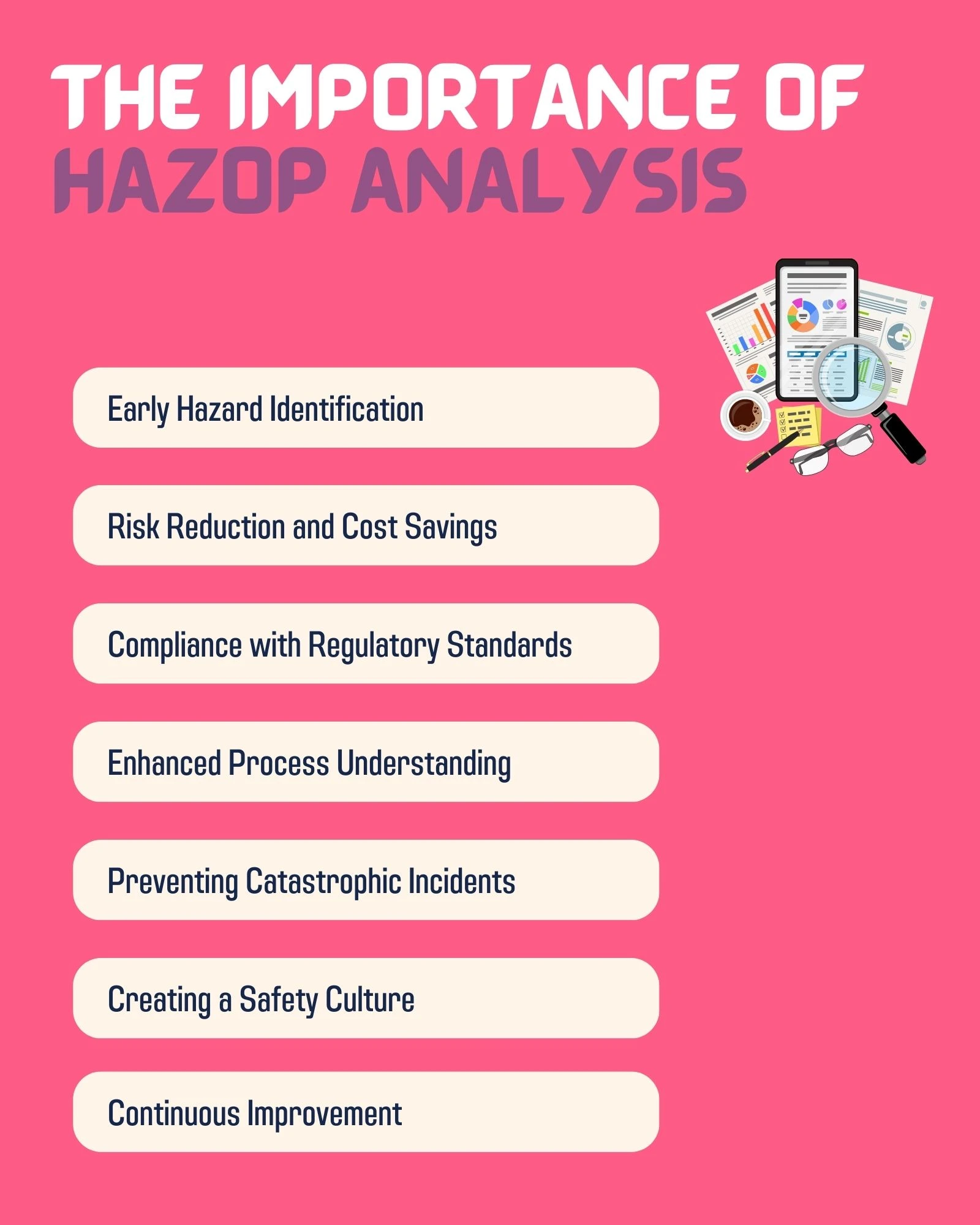

The Importance of HAZOP Analysis

In today's fast-paced industrial landscape, where innovation drives progress, ensuring the safety of processes and systems is non-negotiable. According to a study, The HAZOP methodology is now a globally adopted practice that facilitates hazard analysis for processing units. Let us explore the significance of HAZOP analysis in more depth:

Early Hazard Identification

The early identification of potential hazards is the bedrock of industrial safety. According to AD Little, HAZOP analysis is one of the most potent methods for identifying hazards. Through its meticulous examination, HAZOP shines a spotlight on latent risks that might remain unnoticed in the labyrinth of complex processes. By employing a systematic approach and employing a diverse range of experts, this technique dissects each element of a system. The application of guide words serves as a catalyst, provoking deviations and revealing vulnerabilities. These identified hazards might range from subtle pressure variations to chemical reactions that could spiral into catastrophic incidents. Recognising these dangers at their inception empowers organisations to proactively implement tailored preventive measures, significantly reducing the likelihood of accidents. In essence, HAZOP acts as a vigilant sentinel, safeguarding industries against the unforeseen.

Risk Reduction and Cost Savings

The judicious allocation of resources is pivotal in industrial operations. According to a study, the Hazard and Operability Study is widely acknowledged as a practical tool for evaluating risks. It offers a strategic roadmap by pinpointing high-risk areas within a process. By focusing resources on these critical points, organisations optimise their risk reduction efforts. For instance, a refinery might face multiple potential hazards, but not all risks are created equal. HAZOP aids in categorising risks based on their severity and probability of occurrence. Resources can then be channelled towards mitigating high-risk scenarios, ensuring a more efficient use of finances, time, and manpower. This proactive risk management strategy not only saves costs in the short term but also prevents the exorbitant expenses associated with accidents and their aftermath.

Compliance with Regulatory Standards

In an era of stringent regulations, compliance is not just a legal obligation but a moral responsibility. Industries operate within a framework of rules designed to protect the workforce, the environment, and surrounding communities. HAZOP analysis, by identifying potential non-compliance issues, acts as a safety net, ensuring that organisations adhere to these regulations. The detailed HAZOP report becomes a comprehensive dossier that can be presented to regulatory bodies as evidence of a proactive safety approach. This fosters trust and shields organisations from legal repercussions, fostering a culture of responsible industry practices.

Enhanced Process Understanding

A profound understanding of intricate industrial processes is indispensable. HAZOP compels the study team to delve deep into the system's heart, exploring its intricacies and nuances. This deep dive reveals potential hazards and enhances the team's comprehension of the process's functions. This intimate knowledge equips operators and engineers with the acumen to make well-informed decisions even in high-pressure situations. Understanding the system dynamics allows for anticipatory actions, ensuring the operation runs smoothly under normal conditions and enabling swift, effective responses during abnormal situations. In essence, HAZOP fosters a breed of experts who don't just operate systems but truly understand and master them.

Preventing Catastrophic Incidents

Industries, particularly those dealing with hazardous materials, are haunted by the spectre of catastrophic incidents. These nightmares, ranging from chemical spills to explosions, have far-reaching consequences on human life, the environment, and an organisation's reputation. HAZOP analysis plays a pivotal role in risk management by identifying potential worst-case scenarios. Armed with this knowledge, organisations can craft robust emergency response plans, ensuring the safety of personnel and the swift containment of environmental damage. Moreover, HAZOP acts as a beacon guiding the implementation of preventive measures specifically tailored to thwart these dire situations. By confronting these nightmares head-on, industries fortify their defences, building resilience against the unthinkable.

Creating a Safety Culture

Safety isn’t merely a set of procedures; it's a culture that permeates every level of an organisation. HAZOP analysis acts as a catalyst in this cultural transformation. By incorporating this methodology into their risk management processes, organisations signal a clear message: safety is not just a priority but a shared responsibility. This inclusive approach encourages active participation from employees at all echelons. Individuals become stakeholders in the safety discourse from the shop floor to the boardroom. Near misses are reported, potential hazards are flagged, and safety initiatives become a collective effort. The result is a workplace where safety isn’t just a policy in a handbook but a way of life. Employees, empowered and educated, become the guardians of their own safety, ensuring that the entire organisation operates as a cohesive, vigilant unit.

Continuous Improvement

The industrial landscape is dynamic, with processes evolving, technologies advancing, and new risks emerging. In this ever-changing environment, complacency is the enemy of safety. HAZOP analysis isn’t a static, one-time ritual; it's a dynamic, ongoing process. Regular revisits and updates are imperative. As industries evolve, so do the risks associated with them. By periodically revisiting HAZOP studies, organisations stay ahead of potential threats. They adapt their safety measures, ensuring that they remain robust and relevant. In essence, HAZOP becomes a compass, guiding industries through the ever-shifting terrain of risks, ensuring that safety not only endure but thrives amidst change.

The HAZOP Study Process

The HAZOP study process involves several crucial steps, each meticulously executed to ensure a comprehensive analysis:

1- Formation of the Study Team

The efficacy of a HAZOP study heavily relies on the composition of the study team. This multidisciplinary assembly brings together a wealth of expertise. Process engineers offer technical insights, safety specialists contribute their knowledge of risk assessment, operators provide practical on-ground experience, and managers bring strategic oversight. This diversity ensures that every facet of the process is scrutinised thoroughly. The varied perspectives guarantee a comprehensive analysis, capturing potential hazards and operability concerns from multiple angles. Collaborative synergy becomes the bedrock upon which the study’s success is built.

2- Define the Study Objectives

Setting clear and concise objectives is akin to charting the course for the study. These objectives serve as the guiding stars, ensuring that the team’s efforts are focused and purposeful. They delineate the specific aspects of the process that require examination. Whether it’s scrutinising a new chemical reaction or evaluating the safety protocols of an existing system, these objectives keep the study on track. The clarity of purpose becomes the catalyst that fuels the study team's rigorous exploration.

3- Selection of Study Nodes

The complex industrial processes are akin to intricate puzzles, each piece interdependent on the other. To dissect this complexity, processes are divided into manageable sections called nodes. Each node represents a distinct portion of the process, a compartmentalised universe of valves, pipes, and reactors. This division simplifies the analysis and allows for a focused examination. The study team can delve deep into each part by dissecting the whole into these manageable nodes, leaving no stone unturned.

4- Application of Guidewords

Guidewords, seemingly simple linguistic cues, are the keys that unlock the door to potential deviations. Words like "more," "less," "no," and "part of" are applied to each node. These seemingly innocuous words become catalysts, triggering the imagination of the study team. For instance, applying the guideword "more" to a pressure valve prompts the team to explore the consequences of excessive pressure. Each guideword becomes a lens, magnifying the possibilities of deviations and ensuring no potential hazard or operability concern goes unnoticed.

5- Brainstorming and Identifying Deviations

The study team engages in structured brainstorming sessions within the framework of guidewords. These sessions are akin to creative crucibles where imaginations run wild, exploring the vast landscape of potential deviations. What if there's too much pressure? What if a valve fails to close? What if there's an unexpected power outage? These ‘what-ifs’ aren’t mere speculation but the building blocks of risk assessment. The team identifies possible deviations, each one a potential hazard or operability issue waiting to be unearthed. The depth of these brainstorming sessions is the hallmark of a thorough HAZOP analysis.

6- Risk Assessment

Identifying deviations is merely the first step; the true essence lies in evaluating their impact. Risk assessment becomes the lens through which these deviations are viewed. Each identified hazard or operability concern is meticulously weighed in terms of severity and likelihood of occurrence. This evaluation isn’t just a numerical exercise but a profound analysis considering the worst-case scenarios. A minor fluctuation in pressure might seem inconsequential, but if it escalates, it could lead to catastrophic consequences. By quantifying these risks, the study team prioritises corrective actions, ensuring that efforts are channelled where they are most needed.

Process | Description |

Formation of the Study Team | Experts assemble for multidisciplinary analysis |

Define Study Objectives | Clear objectives guide focused process examination |

Selection of Study Nodes | Divide system into manageable, inspectable sections |

Application of Guidewords | Guidewords provoke deviations exploration creatively |

Brainstorming and identifying Deviations | Structured sessions uncover potential issues |

Risk Assessment | Evaluate identified hazards' severity and likelihood |

Results and Documentation | Hazards identified, recommendations made, findings documents |

Table 1: The HAZOP process

The HAZOP study process is a symphony of expertise, creativity, and systematic analysis. It's not just a methodical examination of industrial processes; it’s a voyage into the unknown, a meticulous exploration that leaves no stone unturned. It's a testament to the commitment of industries toward ensuring not just the efficiency of their operations but the safety and well-being of every individual involved. The HAZOP study process isn’t just a series of steps; it’s a mindset, a culture of thoroughness that permeates every aspect of industrial safety. Through this process, industries transform from entities navigating uncertainties to architects of their destiny, ensuring that their operations are not just productive but also inherently safe.

Results of a HAZOP Study

The HAZOP study generates comprehensive results that form the foundation for further safety measures and process improvements. These results typically include:

Identification of Potential Hazards

At the heart of every HAZOP study lies the revelation of potential hazards lurking within the intricate web of industrial processes. These hazards, often invisible to the untrained eye, are brought into sharp focus through meticulous analysis. From minuscule leaks in pipelines to the malfunctioning of critical safety valves, each potential threat is identified, analysed, and documented. This newfound awareness becomes the cornerstone upon which proactive safety measures are built. By recognising these hazards, industries arm themselves with the knowledge needed to safeguard their operations against the unexpected, ensuring that every risk is met with a corresponding countermeasure.

Operability Enhancements

Beyond identifying hazards, HAZOP studies delve deep into the operational intricacies of industrial processes. In the quest for excellence, these studies unearth operability issues that might impede the seamless flow of operations. These could range from inefficiencies in energy utilisation to suboptimal flow rates in pipelines. Through astute analysis, the study team identifies these bottlenecks and inefficiencies. With this knowledge, industries can fine-tune their processes, optimising every aspect of their operations. This optimisation improves the system's efficiency and translates into substantial cost savings, making the entire operation more agile and competitive.

Recommendations for Risk Reduction

Armed with a comprehensive understanding of potential hazards and operability concerns, the study team formulates specific, actionable recommendations. These recommendations are not generic prescriptions but meticulously crafted solutions tailored to address each identified risk. For instance, a recommendation might entail the installation of redundant safety valves to mitigate pressure-related hazards or implementing real-time monitoring systems to detect anomalies promptly. Each recommendation is a strategic move aimed at reducing the identified risks to acceptable levels. These tailored solutions are not just theoretical; they are the blueprints that guide industries toward a safer, more secure future.

Documentation of Findings

The insights derived from a HAZOP study are not temporary but immortalised as a formal report. This report is not merely a compilation of data; it's a meticulous documentation of findings, recommendations, and the entire analysis journey. This document becomes the guiding light for industries, serving as a blueprint for safety audits, regulatory compliance, and future modifications. It's a comprehensive repository of knowledge, a testament to the dedication of industries toward ensuring the safety of their operations. This documentation isn’t just a formality; it’s a tangible manifestation of a commitment to excellence and safety, a testament to the unwavering resolve to navigate the industry's complexities with wisdom and caution.

In essence, the results of a HAZOP study are not just pieces of information; they are the stepping stones toward a safer, more efficient industrial future. They embody the industry's commitment to its workforce, the environment, and the communities it serves. Each identified hazard, each operability enhancement and each recommendation represents a triumph over uncertainty, ensuring that industries aren't just participants in progress but their architects. Through the results of a HAZOP study, industries pave the way for a future where safety isn't just a goal but a way of life, where operations aren't just efficient but inherently secure, ensuring that every worker returns home safely, every day.

The Role of Labelling in HAZOP

Proper labelling of equipment and processes is pivotal in the effectiveness of HAZOP studies. Accurate labelling ensures that the team can correctly identify nodes and equipment, reducing the chances of overlooking potential hazards. Clear labelling also facilitates smooth communication among team members during the study, promoting a comprehensive understanding of the process. To emphasise the significance of labelling, let’s consider the following table showcasing the impact of clear labelling on hazard identification:

Scenario | Labeling Clarity | Hazard Identification |

Unclear or Absent Labels | Low | Increased likelihood of missed hazards and delays in study process. |

Clear and Accurate Labels | High | Enhanced hazard identification, streamlined communication, and efficient study progress. |

Table 2: Clear labelling and its impact on hazard identification

Clarity Through Accurate Labelling

Labelling, seemingly mundane, forms the bedrock of effective communication during a HAZOP study. Imagine an industrial facility as a vast, intricate maze of pipes, valves, and machinery. Accurate and clear labelling ensures that each component is correctly identified. This precision is not merely for the organisation's sake; it's a fundamental prerequisite for the HAZOP study. When every team member, from engineers to operators, can unequivocally identify equipment and nodes, discussions become focused and efficient. The clarity in labelling eliminates confusion, allowing the study team to direct their attention to the core of the analysis – potential hazards and operability concerns. Without precise labels, the study team would be navigating a foggy landscape, increasing the likelihood of overlooking critical elements, which might lead to incomplete or inaccurate assessments.

Facilitating Smooth Communication

Effective communication is the linchpin of any successful HAZOP study. Accurate labelling is a shared language, enabling seamless communication among team members. During brainstorming sessions, precise labels act as signposts when ideas flow rapidly. Every team member knows exactly what is being referred to when someone mentions a specific valve or pump. This shared understanding accelerates the discussion, ensuring the study progresses without interruptions. Without clear labels, conversations could derail into lengthy explanations or debates about terminology, diverting attention from the critical task at hand – identifying and mitigating potential risks.

Facilitating Comprehensive Understanding

Labelling not only aids verbal communication but also provides a visual context for analysis. When team members can see clearly marked equipment and nodes, they can mentally map the entire process. This visual context is invaluable, especially when applying guide words and brainstorming potential deviations. For example, if a pump is precisely labelled, team members can easily envision the consequences of deviations related to its operation, leading to a more thorough analysis. A visual representation fosters a deeper understanding of the process, allowing the study team to explore deviations holistically. This comprehensive understanding is pivotal in uncovering potential hazards and inefficiencies, ensuring that the analysis is not limited to individual components but encompasses the entire interconnected system.

Preventing Overlooking Potential Hazards

In the labyrinth of an industrial setup, overlooking even a single valve or pipe could have far-reaching consequences. Accurate labelling acts as a safeguard against such oversights. During a HAZOP study, every node and equipment must be scrutinised. Clear labels ensure that no component is left unexamined. When accurately labelled, even the most inconspicuous valves or joints are scrutinised, preventing the study team from inadvertently skipping over them. This precision in examination is vital; it's the assurance that every stone is turned and every nook is explored, leaving no room for unidentified hazards or operability concerns to slip through the cracks.

Promoting Efficiency and Thoroughness

Time is of the essence in any industrial setting. A well-labelled process accelerates the pace of a HAZOP study. When team members can swiftly locate and identify components, discussions become more focused and efficient. Rather than wasting time trying to decipher ambiguous labels or searching for components, the team can dedicate their energy to in-depth analysis and brainstorming. This efficiency not only ensures that the study progresses at an optimal pace but also allows the team to dedicate more time to exploring complex deviations and potential risks thoroughly.

Accurate labelling is not a trivial detail; it's a cornerstone of a successful HAZOP study. It streamlines communication, fosters a shared understanding, provides a visual context, prevents oversights, and promotes efficiency. Through precise labelling, industries provide their study teams with the tools they need to navigate the complexity of their processes with clarity and confidence. Each label becomes a thread in the intricate tapestry of safety, ensuring that the HAZOP study is a meticulous examination and a comprehensive, detailed, and effective analysis that safeguards personnel and processes.

HAZOP in the Oil and Gas Industry

The oil and gas industry, known for its complexity and high-risk nature, heavily relies on HAZOP studies to ensure safe and efficient operations across various phases:

Exploration and Production

In the realm of oil and gas exploration, HAZOP studies are akin to a guiding light. These studies meticulously dissect every process, from drilling operations on land to the complexities of offshore platforms and subsea ventures. Potential hazards such as blowouts, leaks, and fires lurk beneath the surface. HAZOP studies, with their in-depth analysis, identify these risks. For instance, in offshore drilling, the study team assesses the intricate machinery, the high-pressure drilling fluid systems, and the wellhead controls. By recognising potential dangers early, measures can be put in place to safeguard the workers' lives, protect the fragile marine ecosystem, and preserve the costly drilling infrastructure. HAZOP analysis ensures that the oil and gas industry's quest for energy doesn’t come at the cost of environmental integrity and human safety.

Refining and Processing

Refineries and processing plants in the oil and gas industry are intricate labyrinths of interconnected processes. High-pressure systems, heat exchangers handling volatile substances, and vast storage facilities demand rigorous scrutiny. HAZOP studies step in as the guardians of these facilities, identifying safety-critical points in the refining process. For example, when analysing a catalytic cracking unit, the study team explores potential temperature and pressure deviations, ensuring the reactor's integrity and associated systems. HAZOP studies empower the industry to enhance safety protocols, optimise processes, and guarantee the workforce's well-being by pinpointing potential hazards and inefficiencies.

Transportation

Transporting oil and gas products is a high-stakes operation. Pipelines spanning vast distances and tankers navigating treacherous waters are susceptible to many risks. Spills, leaks, and accidents during transit pose significant threats to both human lives and the environment. HAZOP studies focus their gaze on transportation infrastructure and procedures. Whether evaluating the integrity of a pipeline network or the safety protocols aboard an oil tanker, these studies meticulously assess every component. For instance, a HAZOP analysis of a pipeline might examine pressure fluctuations, potential corrosion points, or the impact of external factors like seismic activities. By identifying vulnerabilities, HAZOP studies contribute significantly to the safe transportation of oil and gas products, ensuring that the lifeblood of modern civilization reaches its destination without catastrophic incidents.

The Future of the HAZOP Method

The Hazard and Operability (HAZOP) method, a stalwart in industrial safety, is not frozen in time. As industries evolve and technology advances, the HAZOP method must adapt to meet future challenges. Here’s a glimpse into what the future holds for this indispensable technique:

Integration of Artificial Intelligence (AI) and Machine Learning (ML):

The marriage of HAZOP methodologies with artificial intelligence and machine learning is on the horizon. AI algorithms, fed with vast amounts of historical data, can accurately predict potential hazards and operability issues. By analysing patterns, these algorithms can foresee risks that might be difficult to predict using traditional methods alone. Machine learning models, continuously learning from real-time data, can adapt and enhance the precision of HAZOP analysis. This integration promises a future where predictive analytics play a pivotal role in risk assessment, allowing industries to address safety concerns before they escalate into major issues proactively.

Virtual Reality (VR) Simulations for Enhanced Training:

The advent of virtual reality opens new avenues for HAZOP training and simulations. VR platforms can replicate intricate industrial setups, immersing trainees in lifelike environments. This immersive experience enables realistic HAZOP scenarios, allowing professionals to practise their skills in a risk-free virtual space. Professionals can refine their decision-making abilities and hone their expertise by simulating complex situations. When faced with a real-life HAZOP study, VR simulations ensure that professionals are well-versed in theory and have practical, hands-on experience, making the analysis process more effective and efficient.

Enhanced Data Visualisation and Collaboration Tools:

With the rise of big data, HAZOP studies can harness advanced data visualisation techniques. Interactive dashboards and real-time data analytics allow for a dynamic representation of processes, hazards, and recommendations. These visualisations make complex data accessible and understandable, aiding decision-makers in grasping the nuances of risks and proposed solutions. Additionally, augmented with artificial intelligence, collaboration tools can facilitate remote participation in HAZOP studies. Experts from diverse locations can contribute simultaneously, fostering global collaboration and knowledge exchange. These advanced tools ensure that HAZOP studies are not limited by geographical constraints, allowing a wider array of expertise to be tapped into, ensuring a more comprehensive analysis.

Focus on Sustainability and Environmental Impact:

The future of the HAZOP method will be intricately linked with sustainability. As the world becomes increasingly conscious of environmental impact, HAZOP studies will expand their scope to assess safety and ecological sustainability. Future analyses will delve deeper into the environmental implications of industrial processes, identifying potential hazards that can harm ecosystems and biodiversity. By integrating sustainability metrics into HAZOP studies, industries can align their operations with environmental conservation goals, ensuring that progress is not at the expense of our planet’s well-being.

Continued Training and Professional Development:

As HAZOP methodologies evolve, continuous training and professional development will be paramount. Industry professionals must stay updated with the latest techniques, tools, and best practices. Training programmes, workshops, and certifications will be designed to equip professionals with the skills needed to leverage cutting-edge technologies and methodologies. A skilled workforce ensures that HAZOP studies remain effective, thorough, and adaptive to the ever-changing landscape of industrial processes.

In short, the future of the HAZOP method is bright and dynamic. By embracing innovation, integrating advanced technologies, and fostering a culture of continuous learning, the HAZOP method will continue to be a cornerstone in industrial safety. As industries move forward, the HAZOP method will not only adapt to future challenges but also lead the way in ensuring that progress is not just innovative but also inherently safe and sustainable.

In Conclusion

The Hazard and Operability (HAZOP) study identifies and mitigates potential hazards and operability issues within complex processes. Its systematic approach and risk assessment enable industries to enhance safety, improve operational efficiency, and minimise the occurrence of costly incidents.

The oil and gas industry, one of the most high-risk sectors, greatly benefits from HAZOP studies to protect personnel, the environment, and valuable assets. Through multidisciplinary collaboration and clear communication, HAZOP empowers organisations to make informed decisions that prioritise safety and sustainability.

By embracing the HAZOP methodology, industries worldwide can continue to evolve and innovate, confident in the knowledge that they are safeguarding both their workers and the world in which they operate.

Suppose you’re a professional in the oil and gas sector seeking to deepen your understanding of risk assessment and mitigation. In that case, our course ‘Assessing and Managing Risk in the Oil and Gas Sector’ offers comprehensive insights and practical tools to ensure a safer and more resilient industry, and explains how using the HAZOP study helps with that. Enrol now to take your risk management skills to new heights and contribute to a safer future for our critical industries.