- Table of Contents

- Introduction

- Supply Management Contracting and Logistics

- Vendor Selection

- Contract Negotiation

- Relationship Management

- Continuous Improvement

- Data-Driven Decision Making

- Customisation and Flexibility

- Procurement, Contract & Supply Chain Management

- Cost Savings

- Risk Mitigation

- Supplier Collaboration

- Innovative Procurement Practices

- Contractual Compliance

- Supplier Performance Metrics

- Technological Integration

- Sustainability and Ethical Sourcing

- Corporate Social Responsibility

- Procurement & Contracting Services Training

- Contract Law and Legal Frameworks

- Negotiation Skills

- Supplier Relationship Management

- Ethics and Compliance

- Data Analysis and Technology Integration

- Change Management and Adaptability

- Leadership and Strategic Thinking

- Procurement and Supply Chain Management Best Practices

- Strategic Sourcing

- Performance Measurement

- Technology Adoption

- Collaborative Supplier Relationships

- Demand Forecasting and Inventory Optimisation

- Sustainability and Ethical Sourcing

- Agile Supply Chain Design

- Continuous Improvement Initiatives

- Technology in Contract Logistics

- IoT in Contract Logistics

- Blockchain in Contract Logistics

- Integration of Artificial Intelligence (AI) and Machine Learning (ML)

- Robotic Process Automation (RPA) in Logistics

- Conclusion

Introduction

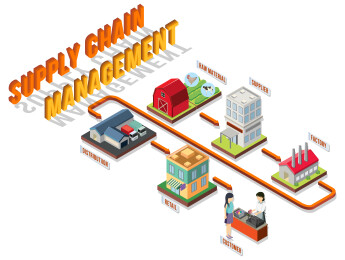

In today's globalised and competitive business landscape, organisations strive to optimise their supply chain operations to gain a competitive edge. One crucial aspect of achieving supply chain excellence is effective contract logistics. Contract logistics refers to outsourcing various logistics activities to third-party providers, enabling companies to focus on their core competencies while leveraging external expertise. In this blog post, we will explore the importance of contract logistics and delve into key topics such as supply management contracting, procurement, contract and supply chain management, and best procurement practices.

Supply Management Contracting and Logistics

Supply management contracting plays a pivotal role in contract logistics. It involves establishing and managing contractual relationships with logistics service providers to ensure seamless movement of goods and materials throughout the supply chain. Effective supply management contracting focuses on the following:

Vendor Selection

The vendor selection process is akin to scouting for the perfect partner in a business marriage. Organisations meticulously assess potential logistics partners, scrutinising their immediate capabilities and adaptability to future challenges. A partner's experience in handling diverse goods, financial stability, and a proven track record in navigating international regulations become pivotal evaluation points. The choice here is not just about hiring a service; it's about entrusting a crucial part of your business to a reliable ally.

Criteria | Description |

Experience | Number of years in the logistics industry. |

Financial Stability | Financial health and stability of the vendor. |

Track Record | Previous successful contracts and client feedback. |

Capability | Range of services offered and technological expertise. |

Compliance | Adherence to legal and regulatory requirements. |

Table 1: Vendor selection criteria

Contract Negotiation

The art of negotiation in supply management contracting cannot be overstated. Negotiating terms and conditions is not merely about striking a deal; it's about aligning the service provider's objectives seamlessly with the organisation's strategic vision. Service levels, pricing structures, performance metrics, and risk-sharing agreements are meticulously outlined. Effective negotiation transcends the immediate benefit; it establishes a foundation for a mutually beneficial, long-term partnership. And, make sure you personalise your potential partners’ experiences. Research indicates that 90% of consumers are attracted to personalised experiences, and 80% are inclined to engage with businesses that employ personalised approaches. Potential partners who discover shared values are more receptive to negotiations and agreeable to your terms.

Relationship Management

Once the ink on the contract is dry, the journey is far from over; in fact, it’s just begun. Relationship management in supply management contracting is about nurturing a symbiotic partnership. Open communication channels, regular performance evaluations, and mutual understanding of goals are the cornerstones. Transparent communication fosters an environment where challenges are faced collectively, successes are celebrated jointly, and innovations are brainstormed collaboratively. It transforms a mere business contract into a relationship where both parties grow together.

Continuous Improvement

A hallmark of effective supply management contracting is the commitment to continuous improvement. This involves regular reviews, not just of the logistics provider’s performance but also of the contract itself. As market dynamics shift and technology evolves, contracts need to adapt. Periodic revisions ensure the partnership remains agile and ready to pivot in response to new challenges and opportunities. Continuous improvement isn’t a choice; the lifeblood keeps the partnership robust and resilient.

Data-Driven Decision Making

In the digital age, data is the currency of informed decisions. Supply management contracting is increasingly relying on data analytics to optimise logistics operations. Real-time data streams from IoT devices, integrated into the supply chain, provide insights into transit times, route efficiency, and inventory levels. This data-driven approach allows for proactive decision-making, enabling organisations to anticipate issues before they escalate, ensuring a smooth flow of goods and minimising disruptions.

Customisation and Flexibility

Standard solutions seldom fit the unique contours of every business. Effective supply management contracting offers customisation and flexibility. Logistics providers tailor their services to meet specific business needs. Whether it’s handling fragile goods, managing temperature-sensitive shipments, or navigating complex customs regulations, a customised approach ensures that logistics operations align seamlessly with the intricacies of the business. This level of tailored service adds a layer of agility to the supply chain, making it responsive to the ever-changing market demands.

In the tapestry of supply chain operations, supply management contracting is the thread that binds everything together. It's not just an outsourcing strategy; it's a strategic partnership that can transform the ordinary into the extraordinary. By understanding the nuances of this partnership, organisations can navigate the complexities of the global market with finesse, ensuring that their goods reach their destinations efficiently, on time, and in pristine condition.

Procurement, Contract & Supply Chain Management

Procurement and contract management are integral components of supply chain management. They involve acquiring goods and services, negotiating contracts, and managing supplier relationships. By integrating procurement and contract management practices into supply chain operations, organisations can achieve several benefits, including:

Cost Savings

Procurement and contract management directly impact an organisation's bottom line. Businesses can save significantly by strategically sourcing materials and negotiating contracts that secure competitive pricing. Whether it's through bulk purchasing, volume discounts, or long-term agreements, every penny saved in procurement contributes to improved profitability.

Risk Mitigation

In the modern business landscape, risks are omnipresent, be it in supply disruptions, quality issues, or regulatory compliance. Effective procurement practices are a bulwark against these uncertainties. Robust supplier selection processes and well-managed contracts ensure minimising the risks associated with the supply chain. This strategic risk mitigation safeguards operations and protects the brand reputation.

Supplier Collaboration

Suppliers are no longer mere vendors but strategic partners in the supply chain. Engaging them early in the product development process fosters innovation and product quality. This close collaboration also speeds up time-to-market, a critical factor in today's fast-paced business environment. Through co-innovation, organisations can bring products to market faster and with a competitive edge.

Innovative Procurement Practices

Procurement is not just about securing the lowest cost; it's about obtaining the best value. Advanced procurement practices include methods like e-sourcing, e-auctions, and spend analysis. E-sourcing platforms enable organisations to identify the most suitable suppliers, while e-auctions create a competitive environment that drives costs down. Spend analysis helps identify areas where costs can be optimised. Such practices are essential for staying ahead in a fiercely competitive market.

Contractual Compliance

Effective contract management ensures that all parties involved adhere to the terms and conditions of an agreement. It's not merely about signing a contract but also about enforcing it throughout its lifecycle. A comprehensive contract management system helps track milestones, manage obligations, and ensure the partnership is aligned with the agreed-upon goals. Compliance reduces the risk of contract disputes and associated costs.

Supplier Performance Metrics

Key Performance Indicators (KPIs) are invaluable tools in supplier performance measurement. Organisations establish KPIs to monitor supplier performance, track service levels, and identify areas for improvement. Businesses can make informed decisions by quantifying supplier performance, rewarding exceptional performance, and proactively addressing underperforming areas.

Technological Integration

In the digital era, technology is not just a luxury but a necessity. Businesses increasingly integrate advanced technologies such as artificial intelligence, machine learning, and blockchain into procurement and contract management. These technologies streamline processes, enhance visibility, and improve decision-making. For instance, contract management software offers an efficient way to monitor and manage contracts, improving compliance by a significant 55%, according to Axdraft. Technological integration is a critical enabler in modern supply chain and contract management.

Sustainability and Ethical Sourcing

The modern consumer is environmentally conscious and values ethical business practices. By integrating sustainability into procurement, organisations can secure environmentally friendly suppliers and promote fair labour practices. These practices demonstrate corporate social responsibility and resonate with consumers, enhancing brand value.

Corporate Social Responsibility

Beyond profit margins and market share, businesses increasingly recognise their role in society. Procurement and contract management play a significant role in this regard. Ethical sourcing, sustainable practices, and community involvement are becoming important components of corporate social responsibility efforts. These initiatives enhance an organisation's reputation and contribute positively to society.

Benefit | Description |

Enhanced Brand Reputation | Positive image among environmentally conscious consumers |

Cost Reduction | Long-term savings savings through energy efficiency and west reduction. |

Regulatory Compliance | Adherence to environmental regulations, avoiding fines and penalties. |

Supplier Loyalty and innovation | Attracts eco-friendly suppliers, fostering innovation and collaboration. |

Access to Green Markets | Entry into markets demanding sustainable products, expanding customer base. |

Table 2: Benefits of sustainable practices

The dynamic synergy between procurement, contract management, and supply chain operations is more than just an operational necessity. It's a strategic approach that ensures an organisation's agility, cost-effectiveness, and reputation in a competitive marketplace. Integrating these functions isn't a mere trend but a transformative journey toward excellence, where every aspect of the supply chain is optimised to meet the demands of today's ever-evolving business world.

Procurement & Contracting Services Training

To excel in procurement and contract management, organisations must invest in employee training and development programmes. These programmes equip procurement professionals with the necessary skills and knowledge to handle complex negotiations, manage contracts effectively, and build strong supplier relationships. Key training areas may include:

Contract Law and Legal Frameworks

Understanding the intricacies of contract law is fundamental. Procurement professionals must grasp the nuances of legal obligations, permissible clauses, and the rights and responsibilities of all parties involved. A comprehensive training programme in this area equips individuals to comprehend complex legal jargon and confidently draft, negotiate, and manage contracts. By mastering legal frameworks, professionals ensure that their organisations remain compliant and legally protected.

Negotiation Skills

Negotiation is an art form that can make or break a deal. Effective negotiation skills are essential for securing favourable terms, resolving conflicts, and nurturing long-term supplier relationships. Negotiation training programmes delve into various techniques, strategies, and approaches, empowering professionals to achieve win-win outcomes. Negotiation training goes beyond theory; it provides practical scenarios and simulations, allowing individuals to hone their skills in a controlled environment.

Supplier Relationship Management

Supplier relationships are the lifeblood of procurement and contracting services. Effective communication, performance measurement, and conflict resolution are key components of supplier relationship management. Training in this area emphasises developing interpersonal skills, understanding cultural nuances, and fostering collaboration. By learning how to build and sustain positive supplier relationships, professionals enhance supplier performance, drive innovation, and ensure the reliability of the supply chain.

Ethics and Compliance

Ethics and compliance with industry regulations are non-negotiable in today's business environment. Training programmes focused on ethics and compliance educate professionals about ethical sourcing, fair trade practices, and the legal obligations associated with procurement and contracting services. This training safeguards the organisation's reputation and aligns its practices with global standards, fostering trust among stakeholders.

Data Analysis and Technology Integration

The digital transformation of procurement and contracting services demands proficiency in data analysis and technology integration. Training programmes in this area equip professionals with skills in data interpretation, visualisation, and utilisation of advanced analytics tools. Additionally, understanding the integration of technologies such as artificial intelligence, blockchain, and contract management software is crucial. Training in these areas ensures that professionals can harness the power of data-driven decision-making and optimise processes through technology.

Change Management and Adaptability

The business landscape is constantly evolving. Procurement and contracting professionals must manage change and adapt to new methodologies, technologies, and market trends. Training programmes focusing on change management provide insights into change theories, implementation strategies, and techniques for overcoming resistance. Professionals trained in change management are better equipped to lead their teams through transitions, ensuring that the organisation remains agile and competitive.

Leadership and Strategic Thinking

Elevating procurement and contracting services from operational functions to strategic assets requires leadership skills and strategic thinking. Leadership training programmes cultivate qualities such as decision-making, team building, and conflict resolution. Moreover, strategic thinking training enables professionals to align procurement and contracting goals with overall business objectives. Professionals trained in leadership and strategic thinking become instrumental in driving organisational success, fostering innovation, and ensuring long-term sustainability.

In the realm of procurement and contracting services, training is not just an investment; it's a strategic imperative. Organisations prioritising continuous learning empower their professionals to navigate challenges, seize opportunities, and contribute significantly to the company's growth. By fostering a culture of continuous improvement and knowledge enhancement, businesses not only enhance the capabilities of their workforce but also position themselves as leaders in the competitive landscape.

Procurement and Supply Chain Management Best Practices

Implementing best practices is crucial to optimising procurement and supply chain management processes. Here are some key practices that organisations should consider:

Strategic Sourcing

Strategic sourcing goes beyond merely finding the cheapest supplier. It involves a meticulous analysis of the total cost of ownership. By conducting comprehensive market research and leveraging economies of scale, organisations can identify suppliers that offer competitive prices and ensure high-quality products and timely deliveries. Strategic sourcing forms the foundation for sustainable partnerships, laying the groundwork for long-term success.

Performance Measurement

Establishing Key Performance Indicators (KPIs) is indispensable for monitoring supplier performance. KPIs provide quantifiable metrics, enabling organisations to assess supplier efficiency, product quality, delivery timelines, and customer service. Regular performance evaluations help identify areas for improvement, recognise exceptional service, and foster continuous enhancement. Data-driven decision-making rooted in performance metrics ensures informed supplier management.

Technology Adoption

Embracing cutting-edge technologies is pivotal in modernising procurement and supply chain management. Artificial intelligence, machine learning, and blockchain are revolutionising these fields. For instance, advanced analytics provide actionable insights, empowering organisations to forecast demand, optimise inventory, and streamline distribution. Moreover, contract management software enhances compliance by automating contract tracking and management, minimising risks associated with manual processes.

Collaborative Supplier Relationships

Supplier collaboration isn’t just a buzzword; it’s a strategic imperative. Engaging suppliers as strategic partners fosters innovation, improves product quality, and reduces time-to-market. Early involvement of suppliers in the product development process taps into their expertise, ensuring that the final product aligns with market demands. Collaborative relationships also enhance communication, allowing for swift issue resolution and joint problem-solving.

Demand Forecasting and Inventory Optimisation

Accurate demand forecasting is a cornerstone of effective supply chain management. By leveraging historical data, market trends, and predictive analytics, organisations can anticipate demand fluctuations and adjust their inventory levels accordingly. Inventory optimisation ensures that stock levels are neither excessive nor insufficient, minimising holding costs while meeting customer demands. This balance is achieved through sophisticated algorithms and data-driven insights.

Sustainability and Ethical Sourcing

In the era of corporate social responsibility, sustainability isn’t just a choice; it’s an ethical obligation. Organisations are increasingly integrating sustainability considerations into procurement practices. This involves selecting environmentally responsible suppliers, promoting fair labour practices, and reducing the supply chain's carbon footprint. Ethical sourcing aligns with global sustainability goals and enhances brand reputation, resonating positively with socially conscious consumers.

Agile Supply Chain Design

The modern market demands agility. An agile supply chain design allows organisations to respond swiftly to changing market dynamics. This involves flexibility in production processes, versatile logistics networks, and adaptive inventory management. An agile supply chain can accommodate sudden shifts in demand, embracing new product lines and scaling operations efficiently. Agility is the key to remaining competitive in a landscape marked by rapid changes and unforeseen challenges.

Continuous Improvement Initiatives

The pursuit of perfection is never-ending. Organisations committed to excellence embrace a culture of continuous improvement. Regular assessments, feedback loops, and post-mortem analyses of supply chain processes identify bottlenecks and inefficiencies. Continuous improvement initiatives, often rooted in Six Sigma or Lean methodologies, drive ongoing enhancements. This iterative approach ensures that procurement and supply chain operations evolve in tandem with market demands and technological advancements.

In the relentless pursuit of operational excellence, these best practices serve as beacons, guiding organisations toward efficiency, innovation, and sustainability. By incorporating these principles into their core strategies, businesses optimise their procurement and supply chain management and fortify their positions as industry leaders, capable of weathering the storms of change and emerging stronger on the other side.

Technology in Contract Logistics

In the contemporary landscape of contract logistics, technology stands as the cornerstone upon which efficiency, transparency, and innovation are built. Technological advancements are reshaping how organisations manage their logistics operations, from real-time tracking to predictive analytics. Among these advancements, the Internet of Things (IoT) takes centre stage, revolutionising contract logistics in unimaginable ways.

IoT in Contract Logistics

The Internet of Things (IoT) has emerged as a game-changer in contract logistics. Embedded with sensors and connectivity features, IoT devices enable seamless data exchange across the entire supply chain. This real-time data sharing gives organisations unprecedented visibility and control over their logistics operations.

1. Real-Time Tracking and Monitoring

IoT-enabled devices provide real-time tracking and monitoring of shipments. Sensors attached to goods collect data on various parameters, including location, temperature, humidity, and even shock and vibration. This real-time information ensures that organisations are always aware of the status and condition of their products, allowing for proactive decision-making.

2. Predictive Analytics

The data generated by IoT devices serves as a goldmine for predictive analytics. By analysing historical and real-time data, organisations can anticipate supply chain disruptions, demand fluctuations, and even equipment failures. Predictive analytics enable proactive problem-solving, minimising risks and ensuring uninterrupted operations.

3. Condition Monitoring

For goods that are sensitive to environmental conditions, such as pharmaceuticals or perishable goods, IoT sensors provide condition monitoring capabilities. Organisations can monitor factors like temperature and humidity throughout the entire transportation process. Any deviations from the acceptable range trigger immediate alerts, allowing for swift corrective actions to maintain product integrity.

4. Route Optimisation

IoT devices enhance route optimisation by providing detailed insights into traffic conditions, road closures, and weather forecasts. Smart algorithms process this data in real-time, suggesting the most efficient routes for transportation. This optimisation reduces transit times and minimises fuel consumption, contributing to cost savings and environmental sustainability.

5. Inventory Management

Within warehouses and distribution centres, IoT devices facilitate smart inventory management. RFID tags and sensors track the movement and storage conditions of goods. This level of automation ensures accurate inventory levels, reduces the risk of stockouts, and improves order fulfilment rates. Additionally, it enables organisations to implement just-in-time inventory practices, optimising storage space and reducing holding costs.

Blockchain in Contract Logistics

Beyond IoT, blockchain technology is gaining prominence in contract logistics. With its decentralised and immutable ledger system, blockchain offers unparalleled security and transparency, addressing some of the most pressing challenges in logistics.

1. Enhanced Security

Blockchain provides robust security mechanisms, safeguarding data from tampering and unauthorised access. This heightened security is particularly crucial when dealing with sensitive information such as contractual agreements, shipment details, and payment transactions.

2. Smart Contracts

Smart contracts, powered by blockchain, automate and enforce the terms of agreements. In contract logistics, this automation streamlines various processes, such as payment verification upon successful delivery or automatic penalties for delays. Smart contracts reduce administrative overheads, minimise errors, and enhance overall efficiency.

3. Transparency and Traceability

Blockchain's transparent nature allows all stakeholders in the supply chain to access a single, immutable version of the truth. Every transaction and movement of goods is recorded and time-stamped. This transparency not only builds trust among parties but also facilitates end-to-end traceability. In case of disputes or recalls, stakeholders can trace the journey of products through the supply chain with unprecedented accuracy.

Integration of Artificial Intelligence (AI) and Machine Learning (ML)

Artificial Intelligence and Machine Learning algorithms are transforming how organisations optimise their logistics operations. These technologies process vast amounts of data, identifying patterns and trends that human analysis might overlook.

1. Demand Forecasting

AI and ML algorithms analyse historical sales data, market trends, and various external factors to accurately forecast demand. This precise demand forecasting ensures that organisations maintain optimal inventory levels, reducing excess stock and minimising shortages.

2. Dynamic Pricing Strategies

Machine Learning algorithms analyse market demand, competitor pricing, and customer behaviour to recommend dynamic pricing strategies. Contract logistics providers can adjust their pricing based on real-time market conditions, ensuring competitiveness while maximising profitability.

3. Predictive Maintenance

In the context of logistics, predictive maintenance powered by AI enables the proactive servicing of vehicles and equipment. By analysing sensor data from vehicles and machinery, AI algorithms predict when maintenance is required, reducing downtime and preventing costly breakdowns.

Robotic Process Automation (RPA) in Logistics

Robotic Process Automation streamlines repetitive tasks in logistics operations, enhancing efficiency and accuracy.

1. Order Processing

RPA automates order processing tasks such as order confirmation, invoice generation, and inventory updates. This automation reduces processing time and minimises the risk of errors associated with manual data entry.

2. Shipment Tracking and Documentation

RPA tools track shipments in real time, automatically updating stakeholders and generating necessary documentation. This reduces the administrative burden on logistics teams, allowing them to focus on more strategic tasks.

3. Warehouse Automation

RPA-enabled robots automate tasks like picking, packing, and sorting within warehouses. This automation significantly speeds up order fulfilment processes, reduces labour costs, and minimises errors in product handling.

In summary, integrating IoT, blockchain, Artificial Intelligence, Machine Learning, and Robotic Process Automation propels contract logistics into a new era of efficiency and innovation. Organisations harnessing these technologies' power are optimising their operations and future-proofing supply chains. Embracing technology isn’t just a choice; it’s a necessity in the competitive landscape of modern contract logistics.

Conclusion

Contract logistics is a critical enabler for supply chain excellence. By leveraging the expertise of third-party logistics providers through effective supply management contracting, organisations can streamline their supply chain operations, reduce costs, mitigate risks, and enhance customer satisfaction. Additionally, integrating procurement and contract management practices into supply chain operations, comprehensive training programmes, and adoption of best practices can significantly improve overall supply chain performance. In today's dynamic business environment, investing in contract logistics is no longer a luxury but a strategic imperative for organisations seeking a competitive advantage.

In your journey toward mastering the intricacies of contract logistics, consider taking our exclusive course, ‘Becoming an Expert in Contract Management.’ Unveil the secrets of successful negotiations, harness the power of cutting-edge technologies, and learn the art of fostering enduring partnerships. This course isn't just a learning opportunity; it's your ticket to becoming a trailblazer in the world of contract logistics. Enrol now, and let your expertise redefine the future of your organisation!