- Table of Contents

- Introduction

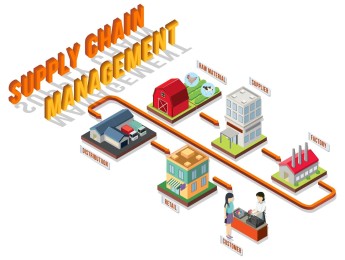

- What Is Supply Chain Management?

- Why Is Supply Chain Management Important?

- Strategic Cost Reduction

- Enhancing Customer Satisfaction

- Gaining a Competitive Advantage

- Risk Mitigation and Business Continuity

- Sustainability and Ethical Practices

- Supply Chain Management Complete Process

- 1. Planning

- 2. Sourcing

- 3. Procurement

- 4. Production

- 5. Logistics

- 6. Distribution

- 7. Customer Service

- Example of SCM

- 1. Planning:

- 2. Sourcing:

- 3. Procurement:

- 4. Production:

- 5. Logistics:

- 6. Distribution:

- 7. Customer Service:

- Industry 4.0 and SCM

- The Future of SCM

- 1. Sustainability and Ethical Practices

- 2. Digital Transformation

- 3. Supply Chain Resilience

- 4. Collaboration and Integration

- 5. Circular Economy Initiatives

- The Green Revolution in Supply Chain Management

- 1. Green Transportation

- 2. Energy-Efficient Warehousing

- 3. Sustainable Packaging Innovation

- 4. Responsible Supplier Practices

- 5. Waste Reduction and Recycling Initiatives

- 6. Life Cycle Assessments and Eco-Design

- Conclusion

Introduction

In today's interconnected world, businesses operate within complex networks that span multiple stages, locations, and stakeholders. Supply chain management (SCM) is the crucial discipline that orchestrates these networks, enabling seamless coordination and process optimization. In this blog post, we will explore the world of SCM, its significance, key processes, real-life examples, the influence of Industry 4.0, and the future of this ever-evolving field.

What Is Supply Chain Management?

Supply chain management refers to the strategic coordination and integration of various activities involved in procuring, producing, and distributing goods or services. It encompasses the movement and transformation of raw materials into finished products, their delivery to end-users, and the management of related information and financial flows. SCM aims to maximise efficiency, minimise costs, enhance customer satisfaction, and ensure sustainability throughout the supply chain.

Why Is Supply Chain Management Important?

Supply chain management plays a vital role in the success of organisations across industries. Here are some key reasons why SCM is of utmost importance:

Strategic Cost Reduction

Effective supply chain management optimises processes, eliminates inefficiencies, and minimises unnecessary costs. Businesses can significantly reduce inventory holding, transportation, and warehousing expenses by streamlining the flow of materials, information, and finances. This strategic cost reduction bolsters the bottom line and ensures that resources are utilised efficiently, allowing companies to invest in innovation and growth.

Enhancing Customer Satisfaction

In an era where customer experience reigns supreme, SCM is pivotal in ensuring timely and accurate deliveries. By aligning production schedules with demand forecasts and optimising distribution channels, businesses can meet customer expectations seamlessly. Satisfied customers translate to repeat business, positive word-of-mouth, and enhanced brand reputation. A well-executed supply chain strategy leads to a loyal customer base, fostering long-term relationships and sustainable growth.

Gaining a Competitive Advantage

A study conducted by Zippia revealed that 57% of companies recognise the significant competitive advantage that a well-managed supply chain provides. Businesses can outperform their competitors by minimising lead times, responding swiftly to market demands, and ensuring superior product quality. SCM enables companies to adapt to changing market dynamics, stay ahead of trends, and capitalise on emerging opportunities, giving them a distinctive edge in the marketplace.

Risk Mitigation and Business Continuity

The business landscape is rife with uncertainties, ranging from natural disasters to geopolitical tensions. SCM equips organisations with the tools to identify potential risks and devise mitigation strategies. Businesses can safeguard their operations from disruptions by diversifying suppliers, establishing contingency plans, and implementing robust quality control measures. This resilience ensures business continuity, even when facing unforeseen challenges, allowing companies to maintain their commitments to customers and stakeholders.

Sustainability and Ethical Practices

In an age where environmental consciousness and ethical sourcing are paramount, supply chain management is central to fostering sustainable practices. Businesses can create a supply chain that aligns with societal values by promoting fair labour, responsible sourcing, and environmentally friendly operations. This commitment to sustainability enhances brand image and resonates with socially conscious consumers, leading to increased market share and positive public perception.

In essence, supply chain management transcends mere logistics and procurement; it is a strategic imperative that shapes the core of business operations. By understanding the intricate interplay of supply chain components and embracing best practices, organisations can navigate the complexities of the global marketplace, ensuring efficiency, customer satisfaction, and enduring success. As businesses continue to evolve, SCM remains the compass guiding them toward operational excellence and sustainable growth.

Supply Chain Management Complete Process

The supply chain management process encompasses various interconnected stages:

1. Planning

The journey begins with meticulous planning, where businesses analyse market demand, study historical data, and employ sophisticated forecasting techniques. Understanding consumer preferences, economic trends, and market dynamics allows companies to make informed decisions. Strategic planning involves anticipating future demand and aligning production and procurement plans to meet customer needs efficiently. This stage sets the foundation for the entire supply chain, acting as a guiding light for subsequent activities.

2. Sourcing

Once the planning phase is complete, organisations begin the sourcing stage, identifying potential suppliers and evaluating their capabilities. Supplier selection is a critical decision, involving considerations such as quality, reliability, cost-effectiveness, and ethical practices. Negotiating contracts and establishing robust supplier relationships are integral parts of this stage. Strong collaborations with suppliers ensure a stable supply of high-quality raw materials, which is essential for maintaining product standards and meeting customer expectations.

3. Procurement

With suppliers in place, the procurement phase commences. This stage involves the actual purchasing of goods or services from selected suppliers. It includes activities such as order placement, supplier management, and contract fulfilment. Procurement professionals play a vital role in ensuring that orders are placed timely, deliveries are tracked, and quality standards are upheld. Effective procurement practices optimise costs and ensure the availability of necessary components for the production process.

4. Production

In the production stage, the raw materials sourced from suppliers are transformed into finished products. This phase encompasses various manufacturing processes, assembly lines, and quality control measures. Consistency and adherence to product specifications are paramount, as they directly impact the end-product quality. During this stage, production efficiency, waste reduction, and adherence to safety standards are key focus areas. Quality control procedures are implemented to identify defects, ensuring that only products meeting stringent quality criteria move forward in the supply chain.

5. Logistics

Logistics forms the backbone of the supply chain, encompassing the efficient movement and storage of products. Activities include transportation, warehousing, inventory management, and order fulfilment. Logistics professionals meticulously plan transportation routes, select appropriate modes of transport, and optimise inventory levels to prevent overstocking or stockouts. Real-time tracking of shipments and inventory levels enables proactive decision-making, ensuring products are where they need to be, precisely when they need to be there.

6. Distribution

The distribution phase involves the physical delivery of products to end-users or retailers. This stage focuses on optimising the final leg of the journey, ensuring timely and accurate deliveries. It involves managing warehouses, coordinating order tracking, and packaging products securely. Distribution centres are vital in sorting, packaging, and preparing products for shipment. Companies employ sophisticated technologies, such as automated sorting systems and barcode scanning, to enhance accuracy and speed during this crucial stage.

7. Customer Service

The journey culminates in the customer service stage, where organisations provide after-sales support and warranty services and address customer queries or concerns. Exceptional customer service is integral to maintaining customer satisfaction and loyalty. Customer service teams act as the bridge between the company and its clients, ensuring that any issues are resolved promptly and effectively. By addressing customer needs and concerns, businesses enhance customer satisfaction and build a loyal customer base, paving the way for repeat business and positive referrals.

The supply chain management process is a well-orchestrated symphony of planning, coordination, and execution. Each stage is intertwined, forming a cohesive chain linking suppliers, manufacturers, distributors, and end-users. Effective supply chain management is not just about moving products from one point to another; it's about creating value, ensuring quality, and nurturing enduring customer relationships. By mastering each phase of the supply chain journey, businesses can achieve operational excellence, enhance customer satisfaction, and thrive in the competitive global marketplace.

Example of SCM

To understand the practical application of supply chain management (SCM), let's take a closer look at how a multinational technology company navigates its intricate supply chain to produce and deliver smartphones. This example will shed light on the various stages and processes involved in SCM and the critical decisions made along the way.

1. Planning:

The company initiates the process by conducting a thorough analysis of market demand. They study sales trends, market research, and customer preferences to forecast their smartphone demand accurately. This information forms the basis for strategic decision-making regarding production volume and procurement planning. The planning phase ensures that the right amount of smartphones will be produced to meet customer needs efficiently without overstocking or understocking.

2. Sourcing:

In the sourcing stage, the technology company identifies and evaluates potential suppliers for key components of their smartphones. These components may include screens, processors, batteries, and other essential parts. The company carefully evaluates potential suppliers based on factors like quality, cost-effectiveness, reliability, and adherence to ethical and environmental standards. Negotiating contracts and establishing long-term partnerships with selected suppliers is critical to secure a stable and high-quality supply of these crucial components.

3. Procurement:

With reliable suppliers in place, the company moves on to the procurement stage. This involves placing orders for the required components with the chosen suppliers. Procurement professionals within the company are responsible for tracking deliveries, ensuring compliance with quality standards, and monitoring delivery deadlines. They play a pivotal role in the smooth execution of the procurement phase, ensuring that the right components are obtained at the right time and in the right quantity.

4. Production:

The company's manufacturing facilities are involved in the production phase. They assemble the smartphones using the sourced components, following a carefully designed production process. Quality control procedures are implemented at every step to ensure the smartphones meet the company's stringent specifications. The production phase aims to maintain consistent product quality and production efficiency.

5. Logistics:

Once the smartphones are ready, they must be transported to regional distribution centres. This transportation involves selecting the most suitable modes, optimising routes, and ensuring products are stored, packaged, and prepared efficiently for shipment. Logistics professionals work to minimise lead times and enhance the overall flow of products within the supply chain. Real-time tracking capabilities are employed to keep tabs on shipments and inventory levels.

6. Distribution:

Smartphones are delivered to retailers or directly to customers in the distribution phase. This stage involves careful warehouse management, order tracking, and efficient packaging to ensure that products reach their final destination promptly. The company may employ sophisticated technologies, such as automated sorting systems and barcode scanning, to enhance the accuracy and speed of the distribution process.

7. Customer Service:

Finally, the smartphone journey culminates in the customer service stage. Here, the company provides customer support and warranty services and addresses any issues or complaints. The goal is to maintain customer satisfaction and loyalty. Customer service teams are trained to resolve customer queries and concerns promptly, ensuring a positive post-purchase experience. Satisfied customers are more likely to return for future purchases and recommend the company to others.

In this real-life example, supply chain management is not just a series of disconnected steps but a well-coordinated process spanning market analysis to customer satisfaction. Each stage of the supply chain is essential to ensure that the right products reach the right customers at the right time. Effective SCM allows the company to meet customer demands efficiently, maintain product quality, and foster customer loyalty, ultimately contributing to its success in the highly competitive technology industry.

Industry 4.0 and SCM

Industry 4.0, characterised by integrating digital technologies into manufacturing and supply chain operations, has significantly impacted SCM. Key technologies driving this transformation include the Internet of Things (IoT), big data analytics, artificial intelligence (AI), blockchain, and automation.

These technologies enable real-time data collection, analysis, and visibility across the supply chain. They enhance forecasting accuracy, optimise inventory management, enable predictive maintenance, facilitate traceability, and support demand-driven production and agile decision-making.

The Future of SCM

Looking ahead, the future of supply chain management holds immense potential for further advancements. Here are some key trends shaping the future of SCM:

1. Sustainability and Ethical Practices

One of the most prominent trends shaping the future of SCM is the emphasis on sustainability and ethical practices. Organisations are increasingly recognising their responsibility to the environment and society. In response, supply chains are becoming greener, focusing on reducing carbon footprints, minimising waste, and promoting fair labour practices. Adopting renewable energy sources, implementing eco-friendly packaging, and ensuring responsible sourcing of raw materials are becoming standard practices. Sustainability certifications and transparency in supply chain operations are expected to become essential criteria for consumers and businesses alike.

2. Digital Transformation

The integration of advanced digital technologies is set to revolutionise SCM. Artificial Intelligence (AI), machine learning, predictive analytics, and Internet of Things (IoT) devices will play a pivotal role. AI-driven predictive analytics will enable more accurate demand forecasting, reducing excess inventory and minimising waste. IoT devices will provide real-time data on the condition and location of products in transit, enhancing visibility and enabling proactive decision-making. Automation, powered by robotics and autonomous vehicles, will streamline warehouse operations and optimise transportation routes. Blockchain technology will ensure transparency, traceability, and security in supply chain transactions, building stakeholder trust. Statistics show, however, that a whopping 63% of companies are still not leveraging technology to monitor their supply chain performance.

3. Supply Chain Resilience

Building resilient supply chains that can withstand disruptions is a top priority for the future. Climate change-related events, geopolitical tensions, and pandemics have highlighted the vulnerability of global supply chains. Companies will invest in risk assessment, scenario planning, and diversification of suppliers and transportation routes. Embracing a multi-sourcing strategy, where critical components are sourced from multiple suppliers, will become commonplace. Additionally, digital tools will facilitate real-time monitoring of supply chain activities, allowing businesses to identify potential risks and implement timely mitigation strategies.

4. Collaboration and Integration

Collaboration among supply chain partners and seamless integration of systems will enhance SCM efficiency. Supply chain networks will evolve into interconnected ecosystems where information flows freely among stakeholders. Cloud-based platforms and data-sharing technologies will enable real-time collaboration, allowing partners to synchronise their efforts, reduce costs, and enhance agility. Supply chain visibility platforms will provide end-to-end visibility, enabling stakeholders to track products across the entire supply chain, from raw material sourcing to final delivery. This transparency will enable rapid responses to changing market demands and supply chain disruptions.

5. Circular Economy Initiatives

The adoption of circular economy principles will gain momentum in the future of SCM. Companies will focus on reducing waste, reusing products, and recycling materials. Remanufacturing, refurbishing, and repurposing products will become standard practices, extending the lifecycle of products and reducing environmental impact. Supply chains will be designed with circularity in mind, ensuring that products and materials can be easily disassembled and repurposed at the end of their life cycles. Circular economy initiatives will contribute to sustainability goals, create new revenue streams, and enhance brand reputation.

In short, the future of supply chain management is marked by a harmonious blend of innovation, sustainability, and resilience. As organisations embrace digital transformation, prioritise ethical practices, and foster collaboration, they will navigate the complexities of the global marketplace with agility and confidence. SCM will cease to be a mere logistical function; it will emerge as a strategic enabler, driving business growth, enhancing customer satisfaction, and contributing to a more sustainable future for all. By embracing these trends, businesses can position themselves at the forefront of the evolving SCM landscape, ensuring success in tomorrow's dynamic and interconnected world.

The Green Revolution in Supply Chain Management

In recent years, a profound shift has been witnessed in the world of supply chain management (SCM) as businesses increasingly recognise the critical importance of environmental sustainability. In fact, statistics show that nearly half of all companies, 48% to be precise, are experiencing pressure to integrate eco-friendly practices into their supply chains. The Green Revolution in SCM represents a transformative journey toward eco-friendly practices, responsible sourcing, and reduced carbon footprints. This revolution aligns with global environmental goals and offers businesses significant advantages, including cost savings, enhanced brand reputation, and a competitive edge. Let’s explore the key facets of this Green Revolution in supply chain management:

1. Green Transportation

One of the cornerstones of the Green Revolution in SCM is the adoption of environmentally friendly transportation options. Companies are transitioning from traditional fossil fuel-powered vehicles to electric, hybrid, and alternative ones. Electric delivery vans, powered by renewable energy sources, are becoming increasingly common, reducing emissions and minimising the ecological impact of transportation. Additionally, innovative approaches such as shared transportation and optimised delivery routes are being employed to reduce the number of vehicles on the road, further lowering carbon emissions.

Transportation Mode | Description | Advantages |

Electric Vehicles | Powered bby electricity, zero emissions | Reduce carbon footprince, eco friendly |

Hybrid Vehicles | Combine fuel and electric power | Increased fuel effeciieincy, lower emissions |

Alternative Fuels | Use non-petroleum fuels like natural gas | Reduce greenhouse gas emissions |

Shared Transportation | Shared rides and deliveries | Reduce greenhouse gas emissions |

Optimised Routes | Smart algorithms reduce transportation diistances | Fuell and time efficiency, lower emissions |

Table 1: Sustainable transportation modes comparison

2. Energy-Efficient Warehousing

Warehouses are energy-intensive facilities, and optimising their energy usage is a key focus of the Green Revolution. Businesses are investing in energy-efficient technologies such as LED lighting, motion sensors, and smart climate control systems. Solar panels are being installed on warehouse rooftops, harnessing renewable energy to power operations. Automation and robotics, used for tasks like inventory management and order fulfilment, are efficient and consume less energy than traditional methods.

3. Sustainable Packaging Innovation

Packaging, a significant contributor to environmental waste, is undergoing a radical transformation. Companies are embracing sustainable packaging materials, including biodegradable plastics, recycled paper, and compostable materials. Moreover, there is a growing trend toward minimalist packaging, reducing excess materials and waste. Businesses are redesigning packaging to be compact, lightweight, and easily recyclable. Smart packaging solutions incorporating QR codes and RFID tags enhance traceability and enable consumers to make environmentally conscious choices.

Material Type | Description | Advantages |

Biodegradable Plastics | Break down naturally, reduce waste. | Environmentally friendly, reduce landfill waste. |

Recycled Paper | Made from post-consumer content. | Renewable, supports recycling efforts. |

Compostable Materials | Biodegradable and enriched soil. | Eco-friendly, minimal environmental impact. |

Minimalist Packaging | Streamlined design, reduced materials. | Efficient, enhance sustainability, reduce waste. |

Smart Packaging Solutions | Incorporate QR codes and RFID tags. | Enhance traceability, eco-conscious consumer choices. |

Table 2: Sustainable packaging materials comparison

4. Responsible Supplier Practices

The Green Revolution extends beyond a company’s direct operations to encompass its entire supply chain. Businesses are collaborating with suppliers who adhere to ethical and sustainable practices. Responsible sourcing involves selecting suppliers, prioritising environmental stewardship, fair labour practices, and ethical conduct. Certifications such as Fair Trade and Forest Stewardship Council (FSC) are becoming essential criteria for supplier selection. By ensuring that every link in the supply chain follows eco-friendly practices, companies contribute to a more sustainable global economy.

5. Waste Reduction and Recycling Initiatives

Minimising waste and promoting recycling are central to the Green Revolution in SCM. Companies are implementing comprehensive waste reduction strategies, focusing on reducing, reusing, and recycling materials. Waste audits are conducted to identify areas for improvement, and initiatives such as composting organic waste and repurposing materials are gaining traction. Recycling programmes for products and packaging materials are being established, encouraging consumers to return products for responsible disposal and recycling.

6. Life Cycle Assessments and Eco-Design

Businesses are increasingly embracing life cycle assessments (LCAs) to evaluate the environmental impact of their products, from raw material extraction to end-of-life disposal. LCAs help identify opportunities for improvement, guiding eco-design initiatives. Eco-design involves creating products with minimal environmental impact, considering factors such as material selection, energy efficiency, and ease of recycling. By designing products with sustainability in mind, companies reduce their overall ecological footprint and contribute to a circular economy.

In summary, the Green Revolution in supply chain management signifies a fundamental shift toward responsible, eco-conscious practices throughout the entire supply chain. Businesses that embrace this revolution not only fulfil their environmental responsibilities but also enjoy tangible benefits, including reduced costs, enhanced brand value, and increased customer loyalty. By pioneering sustainable practices, companies become agents of positive change, fostering a greener future for future generations. The Green Revolution in SCM is not just a trend; it's a fundamental transformation that shapes the future of businesses and the planet.

Conclusion

Supply chain management is a dynamic and essential discipline that drives operational efficiency, cost optimisation, and customer satisfaction across industries. Organisations can gain a competitive edge in today's fast-paced global marketplace by effectively managing the flow of goods, information, and finances. With the integration of digital technologies and embracing sustainable practices, supply chain management is poised to transform further, shaping the future of business operations and driving innovation.

Are you intrigued by the immense possibilities of revolutionising supply chains and becoming a trailblazer in the industry? Dive into the future of business with our cutting-edge course, ‘Supply Chain Management and Logistics.’ Embark on a transformative journey where you'll master the art of seamless coordination, innovation, and sustainability. Equip yourself with the skills to navigate the complexities of modern supply chains, ensuring your place at the forefront of this dynamic and ever-evolving field. Join us now, and let's shape the future of SCM together!