- Table of Contents

- What Is Value Engineering?

- Why Is Value Engineering Important?

- Cost Optimisation

- Enhanced Functionality

- Risk Mitigation

- Sustainable Solutions

- Collaborative Decision-Making

- Value Engineering Steps

- 1. Information Gathering

- 2. Function Analysis

- 3. Creative Idea Generation

- 4. Evaluation and Analysis

- 5. Development and Presentation

- 6. Implementation

- 7. Continuous Improvement and Feedback

- Value Engineering in Construction

- Cost-Effective Material Selection

- Efficient Space Utilisation

- Streamlined Construction Processes

- Energy-Efficient Systems

- Life Cycle Cost Analysis

- Value Engineering and Sustainable Design

- Risk Mitigation and Contingency Planning

- Enhancing Structural Integrity

- Value Engineering in Design

- Early Integration of Value Engineering Principles

- Creative Problem-Solving

- Material Selection and Specifications

- Aesthetic Considerations and Functional Utility

- Design Flexibility for Future Modifications

- Collaborative Approach

- Conclusion

In the ever-evolving world of construction, professionals need to adopt innovative approaches to optimise projects, increase efficiency, and enhance the overall value delivered to clients. One such powerful methodology that has gained significant traction over the years is Value Engineering (VE). In this blog post, we will delve into the intricacies of Value Engineering, exploring its definition, importance, and the steps involved in its implementation. Furthermore, we will specifically focus on how Value Engineering is applied in the construction industry to achieve remarkable results.

What Is Value Engineering?

Value Engineering, often called Value Analysis, is a systematic and collaborative process that aims to improve the value of a project, product, or service while minimising costs. Initially introduced during World War II by Lawrence D. Miles, an engineer at General Electric, Value Engineering has since spread across various industries, including construction, manufacturing, and design.

At its core, Value Engineering is a problem-solving methodology that seeks to optimise resources, enhance functionality, and maximise performance without compromising on quality or safety. It involves a team of experts from diverse disciplines who collectively brainstorm, analyse, and propose innovative alternatives to deliver better value for money.

Why Is Value Engineering Important?

The significance of Value Engineering in the construction industry cannot be overstated. In today's competitive market, projects are expected to meet high-quality standards while staying within budget and completing within tight timelines. Value Engineering offers numerous advantages that address these challenges:

Aspect | Description |

Cost Optimisation | Identifies areas to reduce costs without compromising quality or safety, ensuring projects stay within budget. |

Enhanced Functionality | Encourages creative approaches to improve functionality, aiming to exceed user expectations and improve client satisfaction. |

Risk Mitigation | Conducts thorough analysis of alternatives to proactively address potential risks, minimising costly setbacks and adhering to timelines. |

Sustainable Solutions | Focuses on sustainability by integrating eco-friendly practices and materials, aligning with modern construction standards for environmental impact. |

Table: The Primary Benefits and Goals of Value Engineering in Construction

Cost Optimisation

According to LinkedIn, Value Engineering proves exceptionally adept at uncovering opportunities to save costs. Construction projects are notorious for their tendency to exceed budgets, often due to unforeseen expenses or inefficient resource utilisation. Value Engineering steps in as a systematic approach to curtail unnecessary costs. Value Engineering experts identify areas where expenses can be trimmed without compromising the quality or safety standards by critically analysing every aspect of the project, from materials to labour and technology. This meticulous cost control ensures that projects meet and often stay within the allocated budget.

Enhanced Functionality

Beyond merely cutting costs, Value Engineering emphasises enhancing functionality. Traditional construction approaches might focus solely on meeting the project's basic requirements. However, Value Engineering challenges this norm by encouraging professionals to think creatively. By exploring innovative designs, materials, and technologies, Value Engineering ensures that every project element serves a purpose. Whether it's a residential building or a complex industrial facility, Value Engineering aims to improve the end-user experience. This emphasis on functionality meets the project’s intended purpose and often exceeds user expectations, resulting in higher client satisfaction.

Risk Mitigation

Construction projects inherently involve a plethora of risks, ranging from weather-related delays to supply chain disruptions and safety hazards. Value Engineering mitigates risks by conducting thorough analyses of potential alternatives. By exploring various options at the planning stage, risks associated with specific designs or technologies can be identified and addressed proactively. This early risk management ensures that the project progresses smoothly, minimising the likelihood of costly setbacks and ensuring that timelines are adhered to as closely as possible.

Sustainable Solutions

In the modern construction landscape, sustainability isn’t just a buzzword; it’s a fundamental requirement. Clients, regulatory bodies, and society at large increasingly demand environmentally friendly and energy-efficient buildings and infrastructure. Value Engineering, by its nature, encourages the integration of sustainable practices. This can involve using eco-friendly materials, energy-efficient systems, and designs that minimise the environmental impact. By incorporating these sustainable solutions, Value Engineering reduces the project's carbon footprint and lowers long-term operational costs. This dual benefit aligns construction projects with global efforts to combat climate change and fosters a more responsible approach to building.

Collaborative Decision-Making

Successful construction projects require seamless collaboration among various stakeholders - architects, engineers, contractors, and clients. Value Engineering promotes collaborative decision-making by involving experts from different fields. This interdisciplinary collaboration facilitates open communication, ensuring that all perspectives are considered. By encouraging this synergy of knowledge and expertise, Value Engineering leads to comprehensive solutions. These solutions optimise costs and functionality and foster a sense of shared ownership among stakeholders. This collaborative environment often leads to innovations that might not have been possible within the confines of traditional hierarchical decision-making structures.

In summary, Value Engineering is a beacon of efficiency, sustainability, and innovation in the construction industry. By diligently addressing costs, functionality, risks, and sustainability and fostering collaboration, Value Engineering ensures that construction projects meet the expectations of today's stakeholders and contribute meaningfully to a better, more sustainable future. Its importance lies in its immediate impact on individual projects and its potential to reshape the entire construction industry, paving the way for a more efficient, eco-conscious, and client-focused approach to building.

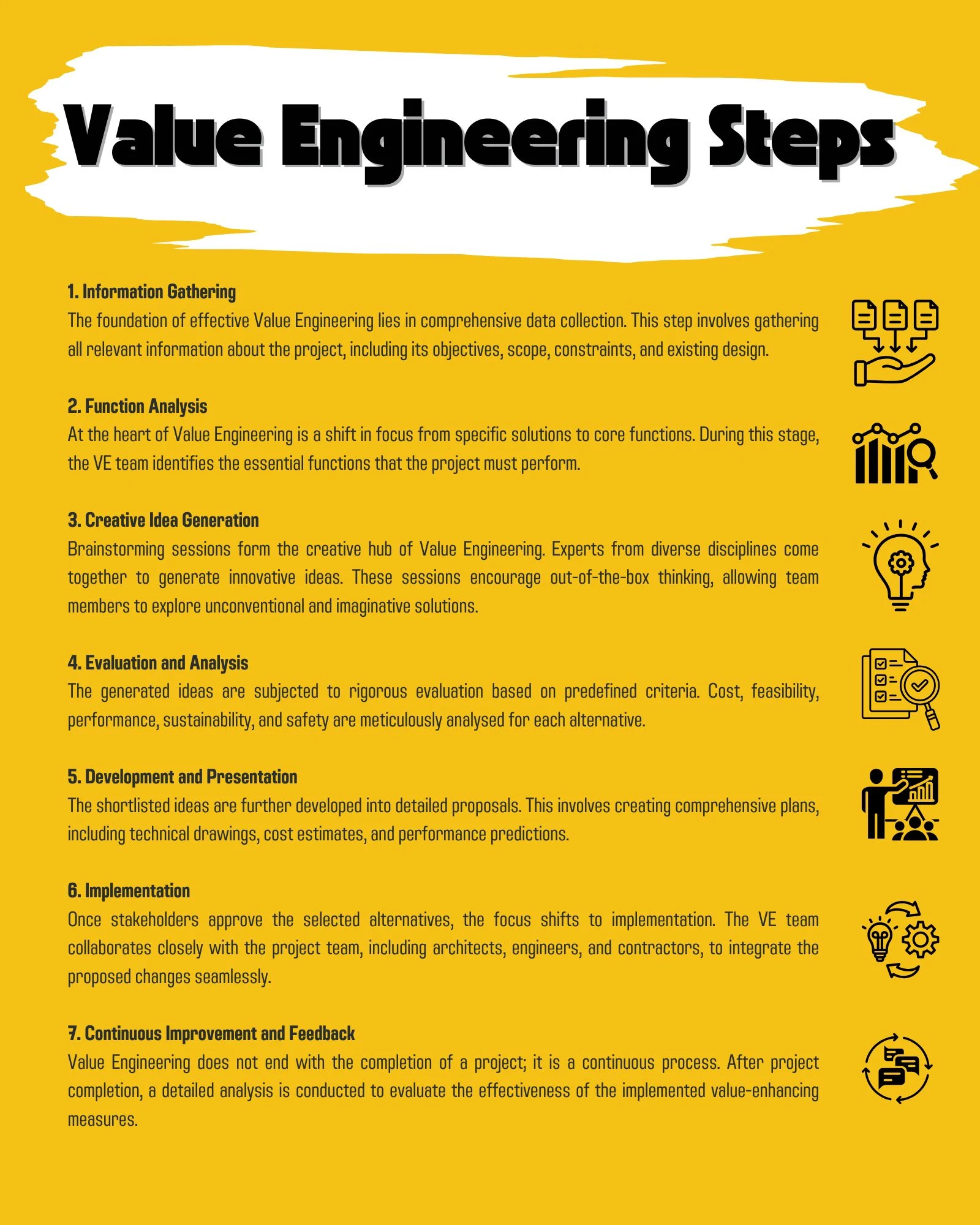

Value Engineering Steps

Value Engineering involves a systematic and structured approach that empowers professionals to identify innovative solutions, optimise costs, and enhance functionality. The process comprises several key steps, each playing a vital role in the overall success of the methodology:

1. Information Gathering

The foundation of effective Value Engineering lies in comprehensive data collection. This step involves gathering all relevant information about the project, including its objectives, scope, constraints, and existing design. Detailed documentation, architectural plans, engineering drawings, cost estimates, and technical specifications are meticulously studied. This wealth of information gives the VE team a deep understanding of the project, enabling them to make informed decisions later in the process.

2. Function Analysis

At the heart of Value Engineering is a shift in focus from specific solutions to core functions. During this stage, the VE team identifies the essential functions that the project must perform. By distilling the project to its fundamental purposes, the team can brainstorm various innovative solutions. For example, in designing a bridge, the core function is to provide safe passage. By concentrating on this function rather than fixating on predetermined bridge designs, the team can explore unconventional yet highly efficient alternatives.

3. Creative Idea Generation

Brainstorming sessions form the creative hub of Value Engineering. Experts from diverse disciplines come together to generate innovative ideas. These sessions encourage out-of-the-box thinking, allowing team members to explore unconventional and imaginative solutions. Value Engineering ensures that all possible avenues are explored by fostering an environment where creativity thrives. Ideas that might seem radical in traditional project planning often find a place in these brainstorming sessions, leading to innovative breakthroughs.

4. Evaluation and Analysis

The generated ideas are subjected to rigorous evaluation based on predefined criteria. Cost, feasibility, performance, sustainability, and safety are meticulously analysed for each alternative. Quantitative and qualitative analyses often involve complex mathematical models and simulations. The VE team can objectively compare various options using a meticulous analytical approach. This step is crucial as it separates feasible ideas from those that might be innovative but impractical for the project.

5. Development and Presentation

The shortlisted ideas are further developed into detailed proposals. This involves creating comprehensive plans, including technical drawings, cost estimates, and performance predictions. These proposals are then presented to stakeholders, including project owners, architects, engineers, and investors. The VE team highlights each solution's potential benefits and cost savings during these presentations. Clear and persuasive communication is essential to convey the value of the proposed alternatives, ensuring stakeholders are well-informed and confident in their decisions.

6. Implementation

Once stakeholders approve the selected alternatives, the focus shifts to implementation. The VE team collaborates closely with the project team, including architects, engineers, and contractors, to integrate the proposed changes seamlessly. Regular monitoring and evaluation are essential during this phase to ensure that the value-enhancing measures are effectively incorporated into the project. Continuous feedback loops and adjustments are made as needed, ensuring the planned enhancements translate into tangible benefits during construction.

7. Continuous Improvement and Feedback

Value Engineering does not end with the completion of a project; it is a continuous process. After project completion, a detailed analysis is conducted to evaluate the effectiveness of the implemented value-enhancing measures. This analysis includes a comparison of initial projections against actual results. Lessons learned and best practices from completed projects are documented and used to refine future Value Engineering processes. This continuous feedback loop ensures that each project's success contributes to the refinement and evolution of Value Engineering methodologies, fostering a culture of ongoing improvement and innovation within the construction industry.

In essence, the Value Engineering steps provide a systematic framework that optimises the current project and enriches the industry's collective knowledge, leading to more efficient, cost-effective, and innovative construction practices in the future.

Value Engineering in Construction

Now that we have explored the fundamentals of Value Engineering, let's examine its practical application in the construction industry.

Cost-Effective Material Selection

Value Engineering allows construction professionals to explore the realm of construction materials. By analysing various materials in terms of cost, durability, availability, and environmental impact, engineers can make informed decisions. For instance, in the construction of high-rise buildings, the choice between steel and concrete structures involves a careful cost-benefit analysis. Value Engineering enables engineers to explore innovative materials that might be more affordable and sustainable without compromising structural integrity.

Efficient Space Utilisation

Value Engineering challenges conventional spatial layouts. Through innovative thinking, architects and engineers can optimise space, reducing wastage and making the most of the available area. This optimisation not only saves costs but can also lead to a more functional and aesthetically pleasing design. For instance, in residential constructions, architects can redesign floor plans to effectively use natural light and ventilation, reducing the need for artificial lighting and HVAC systems.

Streamlined Construction Processes

Value Engineering identifies inefficiencies in construction processes. Construction processes can be streamlined by integrating modern technologies such as Building Information Modelling (BIM) and prefabrication. BIM, for example, allows real-time collaboration between architects, engineers, and contractors, ensuring that the design is optimised for construction efficiency. Prefabrication, however, involves manufacturing components off-site, reducing on-site construction time. Value Engineering evaluates these methods, ensuring they align with the project’s goals and contribute to both time and cost savings.

Energy-Efficient Systems

Energy costs are a significant concern for building owners. Value Engineering promotes the integration of energy-efficient systems such as LED lighting, solar panels, and smart building technologies. These systems reduce operational costs and enhance the building's sustainability quotient. For instance, in commercial buildings, Value Engineering can lead to the incorporation of smart HVAC systems that adapt to occupancy patterns, significantly reducing energy consumption.

Life Cycle Cost Analysis

Value Engineering looks beyond initial construction costs. It incorporates life cycle cost analysis, which evaluates the total cost of owning and operating a building over its lifespan. By considering maintenance, repairs, energy consumption, and potential future renovations, Value Engineering ensures that decisions made during the design and construction phases have a long-term perspective. For example, investing in high-quality, low-maintenance materials might have a higher initial cost but can significantly reduce operational expenses over the building’s lifecycle.

Value Engineering and Sustainable Design

Sustainability is at the core of modern construction practices, and Value Engineering plays a pivotal role in integrating sustainable design principles. It encourages using renewable materials, green roofing systems, rainwater harvesting, and other eco-friendly solutions. By evaluating these options critically, Value Engineering ensures that sustainable choices are both environmentally responsible and economically viable. Sustainability isn’t just a checkbox; it’s a fundamental criterion in the Value Engineering process, ensuring that construction projects are in harmony with the environment.

Risk Mitigation and Contingency Planning

Value Engineering identifies potential risks early in the project lifecycle. By thoroughly analysing various alternatives, including their associated risks, contingency plans can be developed. This proactive approach allows construction teams to address potential issues before they escalate, ensuring that projects stay on schedule and within budget. Whether it's accounting for weather-related delays or supply chain disruptions, Value Engineering equips construction professionals with strategies to navigate unforeseen challenges effectively.

Enhancing Structural Integrity

Value Engineering is crucial in structural engineering. Engineers evaluate different construction methods and materials to ensure the structural integrity of the building. This involves analysing load-bearing capacities, seismic resilience, and durability. Value Engineering allows engineers to explore advanced construction techniques, such as reinforced concrete frames or steel structures, to enhance a building’s ability to withstand various environmental and load stresses, ensuring safety and longevity.

In short, Value Engineering in construction is not just a process; it’s a mindset. It’s a commitment to optimising every aspect of a construction project, from its conceptualisation to its long-term operation. By embracing Value Engineering, the construction industry not only delivers cost-effective and sustainable projects but also shapes the future of urban landscapes, ensuring that buildings are functional, safe, and environmentally responsible. Through its meticulous evaluation of alternatives and its focus on innovation, Value Engineering continues to drive construction projects toward a future where efficiency, sustainability, and excellence coexist harmoniously.

Value Engineering in Design

Value Engineering isn't limited to the construction phase; it has a profound impact on the initial design stage as well. Integrating Value Engineering principles at the design level allows architects and designers to create innovative, cost-effective, and sustainable structures from the very beginning. Here’s how Value Engineering influences the design process:

Early Integration of Value Engineering Principles

When Value Engineering principles are introduced in the design phase, architects can proactively identify potential cost drivers and inefficiencies. By assessing different design elements against predetermined value criteria, designers can make informed decisions about materials, layouts, and structural systems. Early integration ensures the design aligns with the project’s budgetary constraints while maximising functionality and aesthetic appeal.

Creative Problem-Solving

Value Engineering encourages architects to think creatively. By focusing on the essential functions and objectives of the project, designers can explore unconventional design solutions that are both innovative and practical. For example, in the construction of sustainable buildings, architects can incorporate passive design techniques like natural ventilation, daylight harvesting, and green roofs. These solutions reduce operational costs and enhance the building’s environmental performance, aligning with modern sustainability goals.

Material Selection and Specifications

One critical aspect of design influenced by Value Engineering is material selection. Designers evaluate various materials based on their cost, availability, durability, and environmental impact. By analysing these factors, architects can specify materials that offer the best value for money without compromising quality. This meticulous selection process ensures that the chosen materials contribute to the overall efficiency and longevity of the structure.

Aesthetic Considerations and Functional Utility

Value Engineering doesn’t just focus on cost reduction; it emphasises maximising value. This means striking a balance between aesthetics and functionality in the design context. Guided by Value Engineering principles, architects can create visually appealing structures that serve practical purposes. For instance, in designing public spaces, architects can use innovative landscaping and lighting designs that enhance the area’s aesthetic appeal while promoting safety and accessibility.

Design Flexibility for Future Modifications

Value Engineering in design goes beyond the immediate project requirements. It anticipates future needs and changes. Architects can incorporate design flexibility, allowing for easy modifications and expansions in the future. This foresight is particularly valuable in commercial spaces where businesses might need to adapt their layouts based on evolving operational requirements. By designing spaces that can be easily reconfigured, Value Engineering ensures that buildings remain functional and relevant over the long term.

Collaborative Approach

Value Engineering in design fosters collaboration between architects, engineers, and other stakeholders. Regular brainstorming sessions and design charrettes bring diverse perspectives to the table. By encouraging interdisciplinary collaboration, Value Engineering ensures that designs are visually appealing, structurally sound, and economically viable. This collaborative approach often leads to innovative design solutions that might not be apparent in traditional design processes.

Incorporating Value Engineering into the design phase transforms creativity into practicality and vision into reality. It ensures that budgetary constraints don’t compromise architectural innovation but, instead, is enhanced by them. By aligning creative expression with economic efficiency, architects create spaces that are not only visually stunning but also functionally robust and financially sensible. In essence, Value Engineering in design marries imagination with pragmatism, ensuring that every building stands as a testament to both architectural brilliance and economic prudence.

Conclusion

Value Engineering is a powerful tool for the construction industry to achieve cost-effectiveness, optimise performance, and deliver projects exceeding client expectations. By focusing on functionality, encouraging collaboration, and fostering creativity, this systematic approach enables construction professionals to navigate complex challenges and unlock the full potential of their projects.

In a world where sustainability, efficiency, and value are paramount, applying Value Engineering in construction ensures that stakeholders receive the best return on their investment while contributing to a greener and more resilient built environment. Embracing the principles of Value Engineering is not just a prudent business decision; it is a commitment to a better and more prosperous future for all.

Finally, as you embark on your journey to master the art of construction, we invite you to take the next step toward excellence through our comprehensive ‘Construction Site Management/Supervision’ course. Discover the secrets of successful project optimisation, innovative problem-solving, and sustainable construction practices. Equip yourself with the expertise to lead projects with confidence and efficiency. Join our course now and unlock the door to a future where your construction endeavours are not just projects but milestones of brilliance and value. Enrol today and shape a successful career in construction management!

Frequently Asked Questions(FAQ)

1. What sets Value Engineering apart from traditional cost-cutting measures?

Value Engineering stands out because it focuses on improving functionality, performance, and overall value. Unlike traditional cost-cutting methods, which often involve indiscriminate reductions that may compromise quality, Value Engineering meticulously evaluates every aspect of a project. This thorough analysis ensures that cost savings are achieved without sacrificing the project's integrity, resulting in a balanced approach that enhances both efficiency and quality.

2. How does Value Engineering contribute to sustainability in construction?

Value Engineering significantly contributes to sustainability by exploring sustainable alternatives and energy-efficient solutions. By critically evaluating materials, construction methods, and energy systems, Value Engineering helps reduce environmental impact and operating costs over the building's lifecycle. By prioritising eco-friendly options, Value Engineering ensures that construction projects align with global sustainability goals, creating structures that are not only environmentally responsible but also economically viable in the long run.

3. How early in the project should Value Engineering be implemented?

Value Engineering is most effective when applied during the early design stages. Early implementation allows for a comprehensive analysis of design elements, ensuring that cost-effective and innovative solutions are integrated from the project's inception. However, Value Engineering is a flexible methodology and can be adapted and applied at various points in a project's life cycle, depending on the specific challenges and goals faced by the construction team.

4. Does Value Engineering only apply to large construction projects?

No, Value Engineering principles can be applied to projects of all sizes, from small-scale developments to large infrastructure initiatives. Whether it's a residential building, commercial space, or a community project, Value Engineering offers valuable insights. Its adaptive nature allows it to address the unique requirements of each project, making it a versatile approach that enhances the efficiency and value of constructions, regardless of their scale.

5. What role do stakeholders play in the Value Engineering process?

Stakeholder engagement is crucial in the Value Engineering process. By actively involving stakeholders, including project owners, architects, engineers, and end-users, Value Engineering captures diverse perspectives and goals. Stakeholders' input, preferences, and long-term vision significantly influence the alternatives considered during the process. This collaborative approach ensures that the proposed solutions are not only technically sound but also align with the stakeholders' expectations, creating projects that are tailored to meet everyone's needs effectively.