- Table of Contents

- Introduction

- What Are KPIs?

- What Are Procurement KPIs?

- Why Should You Monitor Procurement Performance?

- 1. Strategic Decision-Making

- 2. Operational Efficiency

- 3. Supplier Management

- 4. Continuous Improvement

- 5. Cost Avoidance

- 6. Resource Allocation and Capacity Planning

- 7. Supplier Portfolio Diversification

- How Do You Measure Procurement ROI?

- 1. Define Measurable Objectives:

- 2. Quantify Savings:

- 3. Assess Process Improvements:

- 4. Consider Total Cost of Ownership (TCO):

- 5. Benchmark Performance:

- 6. Analyse Supplier Performance:

- 7. Communicate Results:

- Leveraging Technology for Procurement Performance

- 1. Procurement Software:

- 2. Artificial Intelligence (AI) and Machine Learning:

- 3. Blockchain for Supply Chain Transparency:

- 4. E-Procurement Portals:

- Sustainability in Procurement

- Environmental Impact

- Social Responsibility

- Regulatory Compliance

- The Future of Procurement: Trends and Predictions

- 1. Sustainable Sourcing

- 2. Digital Transformation

- 3. Supply Chain Resilience

- 4. Data Analytics and Predictive Procurement

- Conclusion

Introduction

Procurement performance is critical to organisational success, and its measurement is key to unlocking strategic advantages. By harnessing the power of key performance indicators (KPIs) and effectively monitoring procurement return on investment (ROI), businesses can gain invaluable insights into their procurement processes, drive efficiency, and achieve sustainable growth. In this comprehensive exploration, we will explore the significance of procurement KPIs, why monitoring procurement performance is crucial, and discuss practical approaches to measuring procurement ROI. Join us as we unravel the potential of performance measurement and its transformative impact on procurement operations.

What Are KPIs?

Key Performance Indicators (KPIs) are quantifiable metrics that enable organisations to evaluate their progress towards achieving specific goals and objectives. These indicators are crucial benchmarks to assess performance, monitor trends, and make informed decisions. KPIs vary across industries and departments, highlighting each sector's unique aspects and priorities. By measuring KPIs, businesses can align their activities with strategic objectives and comprehensively understand their overall performance.

What Are Procurement KPIs?

Procurement KPIs are specific metrics that gauge the effectiveness and efficiency of the procurement function within an organisation. They enable businesses to evaluate their procurement processes' performance and impact and identify improvement areas. While the selection of procurement KPIs may vary based on organisational goals and industry, some common examples include:

KPI | Description |

Cost Savings | Measures the amount of money saved through strategic procurement initiatives, negotiation, and supplier management. |

Supplier Performance | Evaluates the quality, delivery reliability, and overall performance of suppliers. |

Procurement Cycle Time | Tracks the time required to complete the procurement process from requisition to delivery. |

Purchase Order Accuracy | Measures the accuracy and completeness of purchase orders to minimise errors and delays. |

Supplier Diversity | Measures the extent to which an organisation engages diverse suppliers to promote inclusivity and social responsibility. |

Table 1: Common Procurement KPIs

By monitoring these and other relevant KPIs, organisations can proactively manage their procurement activities and optimise their performance.

Why Should You Monitor Procurement Performance?

Monitoring procurement performance is a cornerstone of successful modern businesses for a multitude of compelling reasons:

1. Strategic Decision-Making

Data-Driven Insights: Procurement KPIs provide valuable, real-time data that empowers organisations to make informed decisions. By tracking metrics such as cost savings, supplier performance, and cycle time, businesses gain the insights needed to align procurement strategies with broader strategic goals.

Anticipating Trends: Monitoring procurement performance allows for the early identification of market trends and supplier behaviour patterns. This foresight enables businesses to adjust their procurement strategies promptly, ensuring they stay competitive and responsive to changing market dynamics.

Adaptive Strategy: Procurement professionals can make agile and adaptive decisions with performance data at their fingertips. Based on current performance metrics, they can quickly shift supplier relationships, sourcing strategies, or cost-saving initiatives, thus remaining flexible in dynamic markets.

2. Operational Efficiency

Process Optimisation: By continuously tracking procurement KPIs, organisations can identify operational bottlenecks and areas for improvement. For instance, analysing procurement cycle time metrics can pinpoint delays in the procurement process, leading to process optimisation and reduced lead times.

Cost Reduction: KPIs related to cost savings and purchase order accuracy contribute directly to cost reduction efforts. Improved order accuracy reduces costly errors, while effective negotiation strategies based on KPI data can result in significant savings.

Resource Allocation: Effective monitoring enables better resource allocation. Organisations can allocate their procurement resources judiciously, ensuring that staff and budget are deployed where they will substantially impact procurement efficiency.

3. Supplier Management

Enhanced Supplier Relationships: Monitoring supplier performance metrics fosters better relationships with key suppliers. Organisations can provide feedback based on objective data, enabling suppliers to make necessary improvements. This collaborative approach can lead to more reliable, high-quality, and cost-effective supplies.

Risk Mitigation: Procurement performance metrics also aid in risk mitigation. By tracking compliance-related KPIs, organisations can ensure suppliers adhere to regulatory requirements. This mitigates potential legal risks and protects the organisation's reputation.

Supplier Development: KPIs provide a roadmap for supplier development. Organisations can identify underperforming suppliers and work with them to improve their metrics, thus strengthening the supplier base over time.

4. Continuous Improvement

Benchmarking: Regularly monitoring procurement performance allows businesses to benchmark their performance against industry standards and best practices. Benchmarking not only identifies gaps but also highlights areas where organisations are excelling. This knowledge facilitates targeted improvement efforts.

Innovation: Performance data encourages innovation. Organisations can use KPI insights to explore innovative procurement strategies, technologies, and supplier collaborations that can give them a competitive edge.

Competitive Advantage: Continuous improvement driven by performance data ensures that organisations stay ahead of the competition. Organisations can adapt swiftly to market changes, emerging trends, and evolving customer demands by staying proactive.

5. Cost Avoidance

While cost savings are critical to procurement performance, cost avoidance is equally essential. Monitoring procurement KPIs allows organisations to identify potential cost risks early in the procurement process. For instance, organisations can avoid costly errors and delays by tracking purchase order accuracy and supplier performance. Additionally, they can spot supplier-related issues that might lead to disputes or legal expenses if left unaddressed. Cost avoidance protects the bottom line and preserves the organisation's financial integrity.

6. Resource Allocation and Capacity Planning

Efficient resource allocation is key to meeting procurement goals. Organisations can make informed decisions about resource allocation and capacity planning by closely monitoring procurement performance. For instance, if KPIs indicate a significant increase in procurement cycle time or a surge in purchase orders, organisations can adjust staffing levels or invest in automation tools to meet the demand effectively. Effective resource allocation ensures that the procurement team can handle fluctuations in workload without compromising performance or overburdening resources unnecessarily.

7. Supplier Portfolio Diversification

A diversified supplier portfolio enhances resilience in the supply chain. Monitoring procurement performance metrics, especially supplier diversity, can highlight areas where supplier portfolios may be too concentrated. For example, if a significant portion of supplies comes from a single source, it poses a substantial risk in case of disruptions. By monitoring supplier diversity KPIs, organisations can proactively seek out and onboard new suppliers, spreading risk and ensuring a more reliable supply chain. This diversification strategy enhances business continuity and reduces vulnerability to supplier-related disruptions.

In summary, monitoring procurement performance is not a mere formality but a strategic imperative. It enables organisations to make data-driven decisions, optimise operations, build stronger supplier relationships, and continuously improve in a rapidly changing business landscape. The benefits of diligent performance monitoring extend far beyond the procurement department, impacting the overall success and competitiveness of the entire organisation.

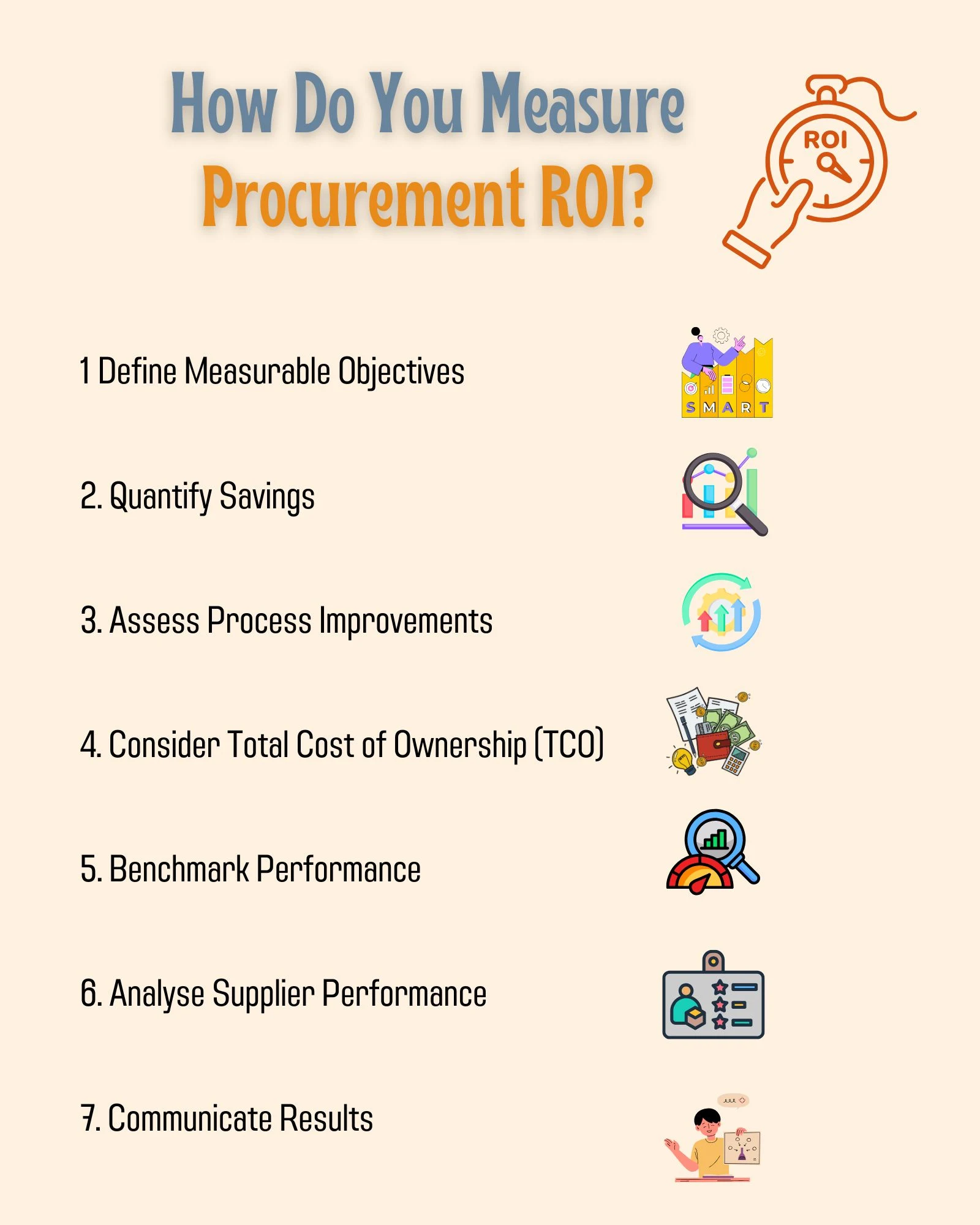

How Do You Measure Procurement ROI?

Measuring procurement return on investment (ROI) is essential to evaluate procurement initiatives' effectiveness and financial impact. Here are some steps to measure procurement ROI:

1. Define Measurable Objectives

Clearly articulating measurable objectives is the foundational step in measuring procurement ROI. These objectives should be specific, realistic, and closely aligned with the organisation's broader goals. For instance, if the goal is to reduce procurement costs, the objective could be to achieve a 10% reduction in sourcing expenses within the next fiscal year. Such clarity helps quantify the impact of procurement activities and serves as a guiding principle for procurement teams, ensuring their efforts are focused on strategic outcomes.

2. Quantify Savings

Quantifying savings achieved through procurement initiatives involves more than just tallying the dollar amount saved. It requires a comprehensive analysis of all cost-saving mechanisms. This includes negotiated price reductions, bulk purchasing advantages, vendor consolidation benefits, and process efficiencies gained through automation. By accurately calculating these savings within a specified timeframe, organisations gain a precise understanding of the financial impact that effective procurement can have on the bottom line.

3. Assess Process Improvements

Evaluating the impact of process improvements on procurement ROI involves a holistic examination of efficiency gains and resource optimisation. Beyond just reduced cycle times and improved order accuracy, it also considers factors such as reduced manual intervention, enhanced collaboration with suppliers through digital tools, and increased automation in procurement workflows. Organisations can directly attribute specific cost reductions or productivity enhancements to process enhancements by assessing these improvements, offering a more comprehensive view of their financial implications.

4. Consider the Total Cost of Ownership (TCO)

While purchase price is a significant component of procurement decisions, it's only part of the TCO equation. To measure procurement ROI effectively, it's essential to factor in all costs associated with a procurement decision. This includes maintenance costs, ongoing operational expenses, inventory carrying costs, and potential risks. For example, a seemingly cheaper supplier might result in higher maintenance and support costs, making them less cost-effective in the long run. Evaluating TCO ensures that procurement decisions are made with a comprehensive understanding of their financial impact.

5. Benchmark Performance

Benchmarking procurement performance against industry standards and best practices provides valuable context for measuring ROI. It helps organisations gauge how they fare in comparison to peers and competitors. By doing so, organisations can identify areas where they excel and areas that need improvement. Benchmarking against industry leaders can also inspire innovation and drive initiatives to achieve higher levels of procurement excellence. Furthermore, it offers a basis for setting ambitious yet achievable ROI goals.

6. Analyse Supplier Performance

Supplier performance has a direct impact on procurement ROI. By analysing supplier metrics such as delivery reliability, product quality, and cost-effectiveness, organisations can determine the financial implications of supplier relationships. For instance, a reliable supplier with consistent quality can reduce the costs associated with returns and defects. On the other hand, a supplier with frequent delays can lead to increased carrying costs and potential missed sales opportunities. Analysing supplier performance metrics helps organisations make informed decisions about supplier relationships and their contribution to ROI.

7. Communicate Results

Effectively communicating measured procurement ROI results is crucial for securing ongoing support and recognition within the organisation. It involves presenting the data clearly, concisely, and compellingly to key stakeholders. This communication should highlight the financial impact and emphasise how procurement initiatives align with broader organisational goals. By showcasing the value that procurement brings to the table, organisations can ensure continued support for future improvements and investments in procurement excellence.

Leveraging Technology for Procurement Performance

In today's digital age, technology is pivotal in enhancing procurement performance. Here are some ways organisations can leverage technology for better procurement outcomes:

1. Procurement Software:

Investing in advanced procurement software solutions such as SAP Ariba or Coupa Procurement is pivotal for modern organisations. These solutions automate routine tasks and offer sophisticated features like supplier management, spend analysis, and contract management. Furthermore, they provide real-time visibility into procurement processes, enabling organisations to make data-driven decisions. Whether it's tracking supplier performance or managing procurement requests, the right software can streamline operations, reduce manual errors, and drive cost savings by optimising supplier relationships. With robust reporting capabilities, procurement software empowers teams to monitor KPIs effectively and adapt their strategies in real-time for improved performance.

Software Type | Description |

Spend Analysis | Analyses spending patterns and trends |

Contract Management | Manages supplier contracts efficiently |

Supplier Relationship | Enhances collaboration with supplier |

e-Procurement | Streamline the entire procurement process digitally |

Inventory Management | Efficiently manages inventory levels and orders |

Table 2: Types of Procurement Software

2. Artificial Intelligence (AI) and Machine Learning:

AI and machine learning technologies have the potential to revolutionise procurement. These technologies can analyse vast datasets, predict supplier performance, and identify cost-saving opportunities that might be elusive to human analysts. By leveraging AI-driven insights, organisations can make more informed decisions about supplier selection, pricing negotiations, and inventory management. Moreover, machine learning algorithms can continuously learn from historical procurement data, refining their predictions and recommendations over time. This ensures that procurement strategies become increasingly efficient and cost-effective as the technology matures.

3. Blockchain for Supply Chain Transparency:

Blockchain technology is rapidly gaining traction in procurement due to its transformative potential in supply chain transparency. It provides an immutable ledger that records every transaction transparently and securely. This transparency is invaluable for tracking the authenticity and origin of products, mitigating counterfeiting risks, and ensuring ethical sourcing. For instance, in the food industry, blockchain can trace the journey of products from farm to table, enhancing food safety and quality assurance. By incorporating blockchain into procurement, organisations can build trust with customers and stakeholders, reduce the risk of supply chain fraud, and bolster their reputation for ethical and transparent business practices.

4. E-Procurement Portals:

E-procurement portals serve as a central hub for supplier interactions. They facilitate efficient procurement processes and foster collaboration between buyers and suppliers. These portals enable organisations to negotiate contracts, track orders, and manage supplier relationships in a digital environment. Additionally, e-procurement portals enhance communication, reducing errors and delays associated with manual processes. Furthermore, they provide a repository for procurement data, which can be leveraged for performance analysis and strategic decision-making. By embracing e-procurement portals, organisations can enhance transparency, streamline supplier interactions, and promote efficiency in procurement operations, ultimately leading to improved performance.

These technological advancements in procurement enhance efficiency and enable organisations to make more strategic decisions. By embracing these technologies, organisations can optimise procurement performance, drive cost savings, and foster stronger relationships with suppliers, positioning themselves for success in an increasingly competitive business environment.

Sustainability in Procurement

Sustainable procurement is gaining prominence in today's socially and environmentally conscious world. Organisations are increasingly focusing on environmentally responsible and socially ethical procurement practices. Here's why it matters:

Environmental Impact

Sustainability in procurement extends beyond cost considerations. It involves reducing the environmental footprint of the products and services an organisation procures. This includes sourcing materials and products that are eco-friendly, energy-efficient, and have minimal environmental impact throughout their lifecycle. Sustainable procurement practices can reduce energy consumption, lower emissions, and generate less waste. By prioritising environmental responsibility, organisations contribute to global sustainability goals and position themselves as socially and environmentally conscious entities, resonating with increasingly eco-aware consumers.

Social Responsibility

Promoting social responsibility in procurement entails fostering diversity, equity, and inclusion throughout the supply chain. It involves actively seeking out diverse suppliers and ensuring fair labour practices among suppliers and subcontractors. Organisations can enforce supplier codes of conduct that align with ethical standards, preventing issues such as child labour, forced labour, and discrimination. Such efforts uphold human rights and enhance the organisation's reputation as a socially responsible entity. Consumers, investors, and stakeholders increasingly favour companies that are committed to ethical and inclusive business practices.

Regulatory Compliance

Many regions and industries have stringent regulations related to sustainability and ethical sourcing. Non-compliance can lead to legal issues, fines, and damage to a company's reputation. Procurement teams must stay vigilant in monitoring and ensuring adherence to these regulations. Sustainability KPIs can serve as a proactive compliance means, helping organisations identify potential risk areas. Regularly tracking these KPIs ensures the organisation stays within legal boundaries and maintains its reputation as a compliant and responsible business entity.

Sustainability in procurement is not just a moral imperative; it's a strategic advantage. Organisations prioritising environmental and social responsibility are better positioned to attract environmentally conscious consumers, reduce risk exposure, and align themselves with regulatory requirements. Moreover, it is committed to long-term sustainability, ensuring businesses remain ethical, competitive, and resilient in an evolving marketplace.

The Future of Procurement: Trends and Predictions

The world of procurement is constantly evolving. Here are some emerging trends and predictions that will shape the future of procurement:

1. Sustainable Sourcing

Sustainability will continue to be a key focus, with more organisations adopting sustainable sourcing practices and incorporating environmental and social criteria into supplier selection.

2. Digital Transformation

Integrating digital technologies like AI, blockchain, and IoT will further streamline procurement processes, making them faster and more efficient.

3. Supply Chain Resilience

Recent disruptions have highlighted the importance of supply chain resilience. Procurement will increasingly focus on diversifying suppliers and building robust supply chain networks.

4. Data Analytics and Predictive Procurement

Advanced data analytics and predictive models will enable proactive procurement decision-making, allowing organisations to anticipate market trends and supplier performance.

As organisations navigate these exciting changes in the procurement landscape, monitoring performance through KPIs and ROI analysis will remain a cornerstone of success.

Conclusion

Measuring procurement performance through the use of KPIs and ROI analysis is crucial for organisations seeking to enhance their operational efficiency, mitigate risks, and drive continuous improvement. By regularly monitoring procurement performance and leveraging data-driven insights, businesses can optimise their procurement processes, foster supplier relationships, and achieve sustainable growth in today's competitive landscape. Embracing a performance measurement and improvement culture empowers organisations to make informed decisions, capitalise on opportunities, and remain agile in an ever-evolving business environment.

If you are interested in pursuing a procurement career path or are just starting out, make sure to check out our course, ‘Procurement Sector Category Management’ that provides in-depth knowledge and practical skills to excel in the procurement field. Equip yourself with the tools and expertise to navigate the intricacies of procurement and contribute to organisational success.